Datasets

Standard Dataset

Tri-Axial Vibro-Dynamic Stone Classification Dataset (TVDSC)

- Citation Author(s):

- Submitted by:

- Usame OZ

- Last updated:

- Thu, 11/21/2024 - 12:10

- DOI:

- 10.21227/at0x-8q72

- Data Format:

- License:

1681 Views

1681 Views- Categories:

- Keywords:

Abstract

Experiment Details:

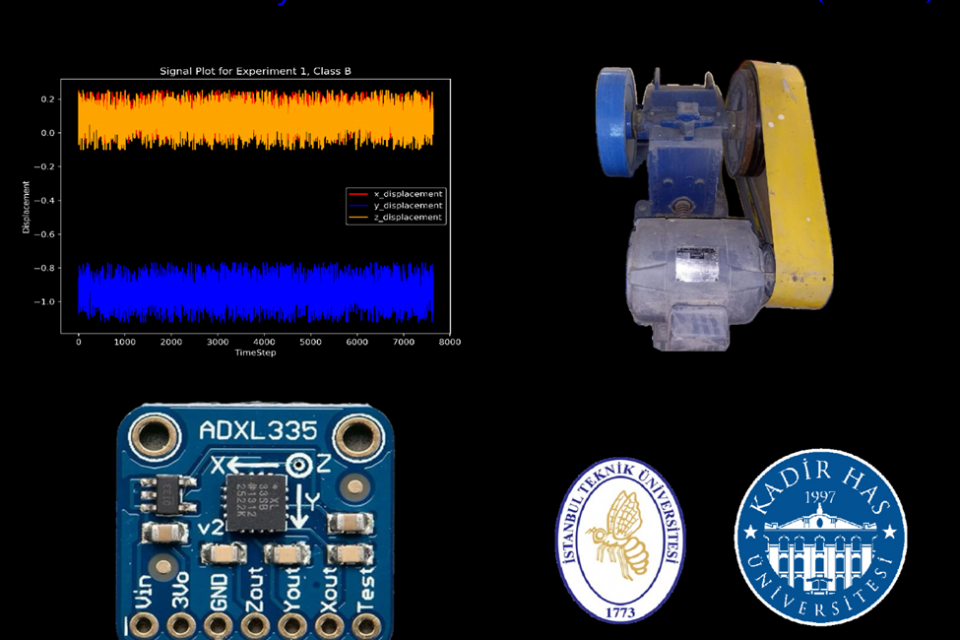

The experiments were conducted at the pilot plant within the Mineral Processing Engineering Department of Istanbul Technical University (ITU), Faculty of Mines. The vibration sensor used in these experiments was the ADXL-335, a three-axis accelerometer known for its high performance and precision in detecting motion across the X, Y, and Z axes. The ADXL-335 converts mechanical vibrations into analog electrical signals that can be further processed into digital formats for analysis. Its ability to provide analog outputs allows for easy integration with data acquisition systems, and the sensor's durability and power efficiency make it highly suitable for industrial and academic applications.

In addition to the vibration sensor setup, the jaw crusher used in the experiments was an Ersel brand laboratory-type crusher connected to a 3kW Westing House induction electric motor operating at 1455 rpm. The motor was powered by a 380-volt three-phase system and connected to the crusher via a belt-pulley method. The Closed Side Setting (CSS) of the crusher was fixed at 18mm for all experiments, as specified by the laboratory staff. This consistent setup allowed for precise control over the material being processed, enabling the reliable collection of vibration, temperature, and current data during the operation of the crusher.

Dataset Identification:

The Tri-Axial Vibro-Dynamic Stone Classification Dataset (TVDSC) consists of vibration data recorded during controlled crashing experiments on stones of three distinct size categories: Size A (50-80 cm), Size B (35-50 cm), and Size C (19-35 cm). For each stone size, multiple experiments were conducted to capture the vibrations caused by the crashing process. Displacement measurements were taken along three axes (X, Y, Z) in unit g (gravity - 9.81 m/s2) at 1 millisecond intervals, ensuring high temporal resolution. To account for sensor inconsistencies across the three axes, the recorded displacement values for each 1 ms interval were averaged across the three dimensions. This approach minimizes potential sensor discrepancies and provides a more consistent representation of the vibrational data.

The dataset includes the following attributes:

Class: Stone size category (A, B, or C).

· TimeStep: Time in milliseconds (starting from 1).

· Experiment_No: Identifier for each crashing experiment.

· x_displacement: Displacement along the X-axis.

· y_displacement: Displacement along the Y-axis.

· z_displacement: Displacement along the Z-axis.

To ensure robust model evaluation and avoid data leakage, we suggest employing a cross-validation strategy based on the Experiment_No column. This approach involves dividing the data according to distinct fracturing experiments, ensuring that data from the same experiment is not shared across training and testing sets. By partitioning data this way, the model's ability to generalize across different fracturing conditions can be more rigorously evaluated, providing a more realistic performance assessment when applied to new, unseen experiments.

This dataset is structured to facilitate research into material classification based on vibrational responses, with consistent measurements derived from tri-axial data. It provides a valuable resource for developing predictive models that can classify stone types based on their dynamic behavior under mechanical stress. The data's granularity and multivariate nature make it suitable for various machine learning and signal processing applications, including time-series analysis, feature extraction, and multivariate classification tasks.

The Tri-Axial Vibro-Dynamic Stone Classification Dataset (TVDSC) consists of vibration data recorded during controlled crashing experiments on stones of three distinct size categories: Size A (50-80 cm), Size B (35-50 cm), and Size C (19-35 cm). For each stone size, multiple experiments were conducted to capture the vibrations caused by the crashing process. Displacement measurements were taken along three axes (X, Y, Z) in unit g (gravity - 9.81 m/s2) at 1 millisecond intervals, ensuring high temporal resolution. To account for sensor inconsistencies across the three axes, the recorded displacement values for each 1 ms interval were averaged across the three dimensions. This approach minimizes potential sensor discrepancies and provides a more consistent representation of the vibrational data.

The dataset includes the following attributes:

Class: Stone size category (A, B, or C).

· TimeStep: Time in milliseconds (starting from 1).

· Experiment_No: Identifier for each crashing experiment.

· x_displacement: Displacement along the X-axis.

· y_displacement: Displacement along the Y-axis.

· z_displacement: Displacement along the Z-axis.

To ensure robust model evaluation and avoid data leakage, we suggest employing a cross-validation strategy based on the Experiment_No column. This approach involves dividing the data according to distinct fracturing experiments, ensuring that data from the same experiment is not shared across training and testing sets. By partitioning data this way, the model's ability to generalize across different fracturing conditions can be more rigorously evaluated, providing a more realistic performance assessment when applied to new, unseen experiments.

This dataset is structured to facilitate research into material classification based on vibrational responses, with consistent measurements derived from tri-axial data. It provides a valuable resource for developing predictive models that can classify stone types based on their dynamic behavior under mechanical stress. The data's granularity and multivariate nature make it suitable for various machine learning and signal processing applications, including time-series analysis, feature extraction, and multivariate classification tasks.

Dataset Files

- Original measurement of X axis X.zip (7.93 MB)

- Original measurement of Y axis Y.zip (7.95 MB)

- Original measurement of Z axis Z.zip (2.97 MB)

- Main dataset stone_discrimination_dataset.csv (875.25 kB)

Documentation

| Attachment | Size |

|---|---|

| 979.39 KB |