Mechanical Sensing

This is a dataset of 32 five-second-long vibration recordings. One human used a metal tool to perform one of two tool-mediated surface interactions (tapping or dragging) on the following four different surfaces: sandpaper (hard and rough), acrylic plastic (hard and smooth), rough paper (soft and rough), and rubber (soft and smooth). Each of the eight combinations of interaction and surface were recorded four times.

- Categories:

458 Views

458 Views<p>The technique of electrical impedance tomography (EIT) has been recognized as a promising method to design tactile sensors with continuous sensing capability over a large area. The mechanism of electrical impedance tomography allows reconstructing tactile information within the sensing area based on measurements made only at the boundary. However, spatial performance of EIT-based tactile sensors has demonstrated location dependency in previous reports, which severely affects correct interpretation of tactile stimuli.

- Categories:

218 Views

218 ViewsThe objective of this dataset is the fault diagnosis in diesel engines to assist the predictive maintenance, through the analysis of the variation of the pressure curves inside the cylinders and the torsional vibration response of the crankshaft. Hence a fault simulation model based on a zero-dimensional thermodynamic model was developed. The adopted feature vectors were chosen from the thermodynamic model and obtained from processing signals as pressure and temperature inside the cylinder, as well as, torsional vibration of the engine’s flywheel.

- Categories:

5173 Views

5173 Views

- Categories:

4580 Views

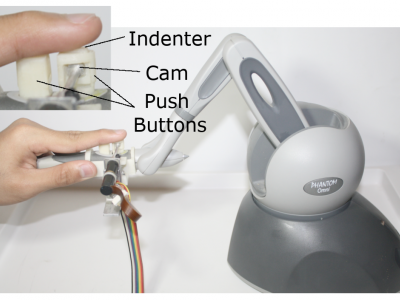

4580 ViewsThe datasets are related to the findings and results of our investigations of the minimal force thresholds perception in robotic surgical applications. The experimental setup included an indenter-based haptic device acting on the fingertip of a participant and a visual system displays grasping tasks by a surgical grasper. The experiments included the display of a set of presentations in three different modes, namely, visual-alone, haptic-alone, and bimodal (i.e., combined). Sixty participants took part in these experiments and were asked to distinguish between consecutive presentations.

- Categories:

480 Views

480 Views

This folder contains the onboard sensor measurements for the EksoGT robotic exoskeleton during experiments with three able-bodied individuals and three non-able-bodied individuals with a spinal cord injury. The data is divided into .mat files by the trial. All able-bodied subjects completed three repetitions of each commanded intent change (Speed Up, Slow Down, and No Change) for each trial set.

- Categories:

232 Views

232 Views

Acoustic measurement data from Multilayer Ceramic Capacitors (MLCCs). Contains preprocessed data from intact and damaged MLCCs for damage detection (classification) purposes.

- Categories:

548 Views

548 Views

This dataset is used to develop an algorithm for evaluating machining quality. When machining a workpiece in a milling process, vibration signals can be recorded by a 3-axis accelerometer, which is attached on the spindle of a CNC milling machine. To evaluate machining quality, the vibration signals can be segmented and extracted the corresponding features, in the time, frequency, and time-frequency domains. After serving with the features, a model can be developed to estimate the machining quality, such as the roughness of a workpiece.

- Categories:

1449 Views

1449 Views

This dataset is used to develop an algorithm for automatic segmenting the collected signals. When machining a workpiece in a milling process, vibration signals can be recorded by a 3-axis accelerometer, which is attached on the spindle of a CNC milling machine. To segment the recorded signals, a moving window (0.5 sec) is applied to sample the vibration signals and manually labeled the corresponding modes, i.e. dry run or milling, of each window. To verify the algorithm, 3 types of operations are provided and recorded in csv format.

- Categories:

626 Views

626 ViewsThis dataset was collected from force, current, angle (magnetic rotary encoder), and inertial sensors of the NAO humanoid robot while walking on Vinyl, Gravel, Wood, Concrete, Artificial grass, and Asphalt without a slope and while walking on Vinyl, Gravel, and Wood with a slope of 2 degrees. In total, counting all different axes and components of each sensor, we monitored 27 parameters on-board of the robot.

- Categories:

253 Views

253 Views