Dataset for PerfCam: Digital Twinning for Production Lines Using 3D Gaussian Splatting and Vision Models

KTH Royal Institute of Technology, SCI; AstraZeneca, Sweden Operations

- Categories:

KTH Royal Institute of Technology, SCI; AstraZeneca, Sweden Operations

This dataset supports a systematic review on the integration of Digital Twins (DT), Extended Reality (XR), and Artificial Intelligence (AI) in Reconfigurable Manufacturing Systems (RMS). The data was collected during a search performed on March 3, 2024, using the Scopus database. Articles published since 2018 were screened based on predefined inclusion and exclusion criteria, resulting in 37 articles selected for qualitative analysis.

Ensuring the safe and reliable operation of autonomous vehicles under adverse weather remains a significant challenge.

To address this, we have developed a comprehensive dataset composed of sensor data acquired in a real test track and reproduced in the laboratory for the same test scenarios.

The provided dataset includes camera, radar, LiDAR, inertial measurement unit (IMU), and GPS data recorded under adverse weather conditions (rainy, night-time, and snowy conditions).

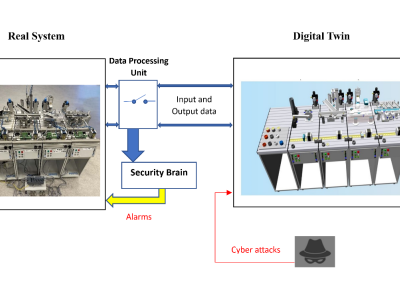

The real system in our experiment comprises four production stations: Pick and place, assembly, muscle compressing and sorting. These modular stations are controlled by Siemens PLC. This is the data gathered from a real manufacturing system and its Digital Twin data when under the denial of service attacks.

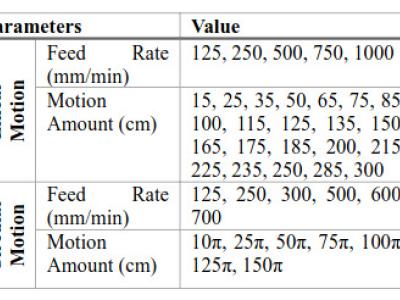

A CNC adapter was utilized together with the software established as part of the GRBL project to operate the CNC adapter, and two data sets were produced for the physical model in order to build the linear and circular motion models. The parameters for motion quantity, motion duration, and feed rate are in the data set.

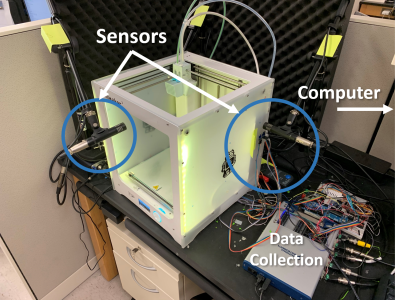

This dataset contains multimodal sensor data collected from side-channels while printing several types of objects on an Ultimaker 3 3D printer. Our related research paper titled "Sabotage Attack Detection for Additive Manufacturing Systems" can be found here: https://doi.org/10.1109/ACCESS.2020.2971947. In our work, we demonstrate that this sensor data can be used with machine learning algorithms to detect sabotage attacks on the 3D printer. By utilizing multiple side-channels, we improve system state estimation significantly in comparison to uni-modal techniques.

The dataset corresponds the measurement that was implemented on the control accuracy of a mixed reality application for digital twin based crane.

This dataset contains requests execution times for comparison of direct requests and requests via API gateway to test API.

The Here East Digital Twin was a six month trial of a real-time 3D data visualisation platform, designed for the purpose of supporting operational management in the built environment.