Composed Fault Dataset (COMFAULDA)

- Citation Author(s):

-

Denys Pestana-Viana (Federal Center for Technological Education of Rio de Janeiro)Luiz Vaz (Federal University of Rio de Janeiro)

- Submitted by:

- Dionisio Martins

- Last updated:

- DOI:

- 10.21227/89ye-ap56

- Data Format:

- Links:

2825 views

2825 views

- Categories:

- Keywords:

Abstract

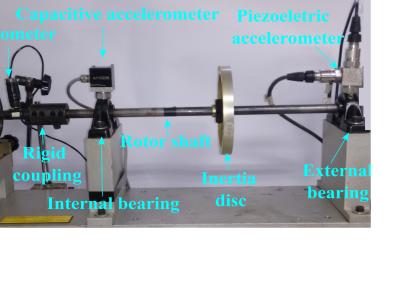

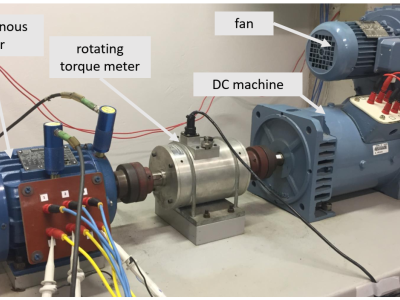

The measurement and diagnosis of the severity of failures in rotating machines allow the execution of predictive maintenance actions on equipment. These actions make it possible to monitor the operating parameters of the machine and to perform the prediction of failures, thus avoiding production losses, severe damage to the equipment, and safeguarding the integrity of the equipment operators. This paper describes the construction of a dataset composed of vibration signals of a rotating machine. The acquisition has taken into consideration seven distinct operating scenarios, with different speed values. Unlike the few datasets that currently exist, the resulting dataset contains simple and combined faults with several severity levels. The considered operating setups are normal condition, unbalance, horizontal misalignment, vertical misalignment, unbalance combined with horizontal misalignment, unbalance combined with vertical misalignment, and vertical misalignment combined with horizontal misalignment. The dataset described in this paper can be utilized by machine learning researchers that intend to detect faults in rotating machines in an automatic manner. In this context, several related topics might be investigated, such as feature extraction and/or selection, reduction of feature space, data augmentation methods, and prognosis of rotating machines through the analysis of failure severity parameters.

Instructions:

The instruction about this dataset is in COMFAULDa_readme; For more details contact: dionisiohmartins@gmail.com

In reply to Upon examining the .csv files by Patricia de Souza