Anomaly Detection with Laser Heat Treatment Thermal Videos

- Citation Author(s):

-

David Atienza (Universidad Politécnica de Madrid)Concha Bielza (Universidad Politécnica de Madrid)Javier Diaz-Rozo (Aingura IIoT)Pedro Larrañaga (Universidad Politécnica de Madrid)

- Submitted by:

- David Atienza

- Last updated:

- DOI:

- 10.21227/7zbf-se57

- Research Article Link:

712 views

712 views

- Categories:

- Keywords:

Abstract

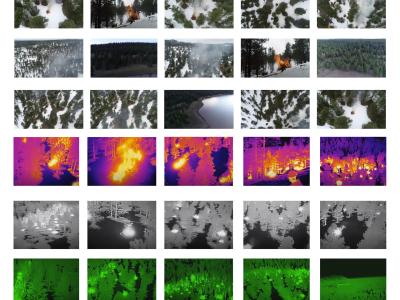

This data set comprises 4223 videos from a laser surface heat treatment process (also called laser heat treatment) applied to cylindrical workpieces made of steel. The purpose of the dataset is to detect anomalies in the laser heat treatment learning a model from a set of non-anomalous videos.

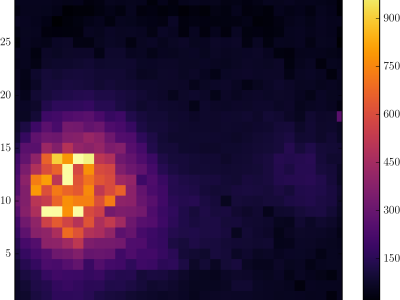

In the laser heat treatment, the laser beam is following a pattern similar to an "eight" with a frequency of 100 Hz. This pattern is sometimes modified to avoid obstacles in the workpieces.

The videos are recorded at a frequency of 1000 frames per second with a thermal camera. The thermal camera pixel values range from 0 to 1024, where higher values means higher temperatures. The thermal camera has a resolution of 32x32 pixels, but a region of interest (ROI) is applied to the videos, so only the laser heat treatment is shown in the videos.

Instructions:

See DESCRIPTION.md for details on the structure of the dataset.