Datasets

Standard Dataset

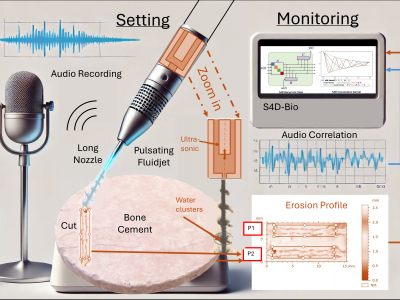

Pulsating Waterjet Cutting

- Citation Author(s):

- Submitted by:

- Melanie Schaller

- Last updated:

- Fri, 02/14/2025 - 05:43

- DOI:

- 10.21227/rp25-g712

- Data Format:

- Links:

- License:

79 Views

79 Views- Categories:

- Keywords:

Abstract

Overview

This dataset contains detailed experimental data from a series of tests conducted to evaluate the performance of a pulsed water jet ablation system. The experiments aim to investigate the effects of various parameters on the ablation process when cutting through material composites such as PLA/Bone Cement and Bone. The experiments involve layers of different materials, including metal, plastic, and bone cement. The primary objective is to understand the material differentiation.

Dataset Content

The dataset comprises 13 major tests, each representing a unique set of operational parameters. For each test, the following parameters were recorded:

Dataset Structure The dataset comprises the following run configuration and results:

- Run-Number: A unique identifier for each experimental run.

- Filename: Name of the file where the results for this run are stored. The file naming convention provides insights into the setup and conditions used in the experiment.

- Material 1 to Material 5: The sequence of materials layered in the experiment. Materials include metals, plastic layers of 10mm thickness, and bone cement of 20mm thickness.

- Average Samplewidth: The total width of the sample measured in millimeters.

- Detection: The type of detection mechanism used, such as PCB (Printed Circuit Board) or USM (Ultrasound Measurement).

- Distance: The distance at which the detection was performed. For USM, this distance is given in meters.

- Pin: Indicates if a pin was used in the experiment setup. If not used, 'no pin' is recorded.

- Standoff-Distance: The distance from the detection device to the sample, measured in millimeters.

- Velocity: The velocity of interaction/incidence with the sample, measured in millimeters per second.

- Comment: Detailed operational timeline notes indicating when each material layer was detected or interacted with in seconds.

According to the velocity and the sample width, the durations over each material can be calculated as follows:

x.x sec - Metal 1.6 sec - Metal - Plastic 0.4 sec - Plastic 1.6 sec - Plastic - Cement 2.4 sec - Cement 0.8 sec - Cement - Plastic 1.2 sec - Plastic 1.6 sec - Plastic - Metal x.x sec - Metal"

The details are summorized in the Excel-Sheet "Explanation_dataset".

Task Good Online Learning Models should be able to adapt as quick as possible to the material changes inside the dataset. Thus the best machine learning models for this dataset will be those that can efficiently identify and adapt to the transitions between different materials during the ablation process.

Training Strategy

- Incremental Learning: Continuously update the model as new data becomes available. This approach ensures the model adapts to new patterns and transitions quickly.

- Learning Rate Scheduling: Adjust the learning rate or employ adaptive learning rate strategies to balance between fast adaptation and stable convergence.

Evaluation Metric

- Evaluate the model's accuracy in predicting material transitions.

- Measure the time taken by the model to adapt to material changes as reflected in the dataset.

- Use precision, recall, and F1-score to assess the model's ability to distinguish between different material interfaces.

Pulsating Waterjet Cutting Dataset

Das Dataset is uploaded to Kaggle.

More from this Author

Dataset Files

- Reader hp5reader.py (411 bytes)

- HP5 to Wav Converter wavconverter.py (1.50 kB)

- Custom Dataset CustomDataset.py (2.04 kB)