Bearing Defect Dataset

- Citation Author(s):

-

Yongkang Peng

- Submitted by:

- Yongkang Peng

- Last updated:

- DOI:

- 10.21227/wbrc-d209

1641 views

1641 views

- Categories:

- Keywords:

Abstract

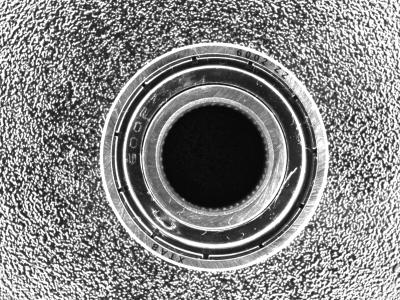

The BD-DET is obtained by professional industrial cameras equipped with a ring light source, with a resolution of 2456×2048. The basic structure of the bearing includes inner and outer rings, a cage, and a sealing cover. Defects are mainly concentrated in the sealing cover area, and are divided into two types: scratches and presses. During the data acquisition process, some data only contain one type of defect, either scratches or presses, while the remaining data contain a mixture of the two defects. The scratch defect appears as a bright line with random shapes and multi-scales, while the press defect appears as an irregular bright spot.

Instructions:

The BD-DET is obtained by professional industrial cameras equipped with a ring light source, with a resolution of 2456×2048. The basic structure of the bearing includes inner and outer rings, a cage, and a sealing cover. Defects are mainly concentrated in the sealing cover area, and are divided into two types: scratches and presses. During the data acquisition process, some data only contain one type of defect, either scratches or presses, while the remaining data contain a mixture of the two defects. The scratch defect appears as a bright line with random shapes and multi-scales, while the press defect appears as an irregular bright spot. To facilitate use, labels can be created using the labelimg tool, and you can format them into either COCO dataset format or VOC dataset format.