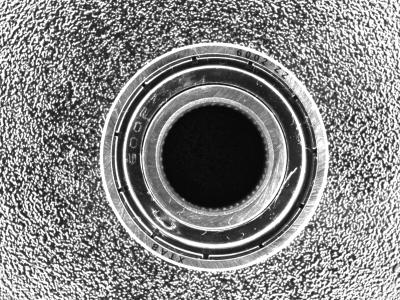

Sensors (VSA001) are used to capture the vibration signals on the bearing (LDK UER20), and a sampling frequency is 25.6 KHz. Samples are collected by a interval of 60 seconds, the length of each sampling is 0.1 seconds, and each sample includes 2560 signals. Multiple sets of vibration signals in normal condition are collected at various time intervals to facilitate model fine-tuning, with a representation of the practical operating conditions. For ease of use, the data file format is .csv.

- Categories: