PCB scans

- Citation Author(s):

-

Nikolaos Dimitriou (CERTH-ITI)

- Submitted by:

- Nikos Dimitriou

- Last updated:

- DOI:

- 10.21227/z902-4t15

- Data Format:

1973 views

1973 views

- Categories:

- Keywords:

Abstract

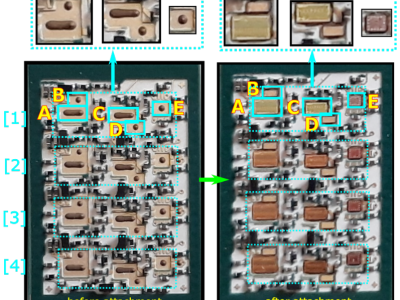

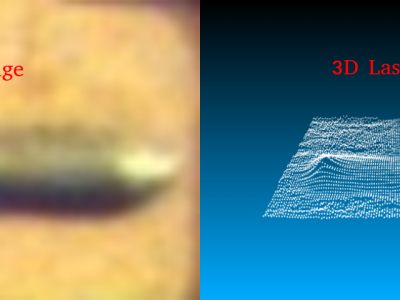

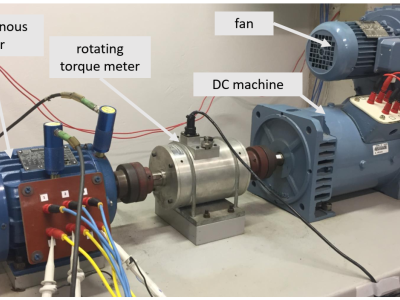

This dataset contains laser scans of PCBs as explained in "Fault Diagnosis in Microelectronics Attachment via Deep Learning Analysis of 3D Laser Scans". On the left and right image, we have a closer look at one circuit

module of a PCB , before and after die attachment. Notice the different types of glue annotated as A, B, C, D and E. On each circuit there are four glue deposits on each type where approximately the same quantity of glue has been placed. As explained

in our paper the top three deposits are used for training and the bottom one for testing. On top, we see a magnified view of glue regions before and after the attachment of dies.

Instructions:

An important step in microelectronics manufacturing is the attachment of ICs on an LCP substrate. To this end, glue is dispensed on the LCP and the critical parameter that has to be monitored is the volume of deposited glue. The dataset contains point cloud from 3 PCBs that were scanned with a high resolution laser sensor as well as ground truth files. Each PCB consists of 18 identical circuit module and each module has 20 placeholders where glue is deposited and afterwards ICs are (will be) attached. For each module, there are 5 different type of placeholders, denoted as A, B, C, D, E, with each type hosting a different type of IC and consequently having different specification in terms of the volume and shape of deposited glue. On the figure above, two circuit modules are depicted (different types of placeholders are marked up), the one on the left having the dispensed glue clearly visible while the one on the right having ICs attached with only a small portion of glue visible around the perigram of the ICs.

Now the dataset is split in two categories of 27 circuit modules, the first one without ICs and the second having ICs attached. Moreover during the preparation of the PCBs the operator of the glue dispenser arranged the setup of the machine and inspected the dispension so that for each module without IC attached there is a correspondence in the quantity of glue deposited with a circuit module where ICs have been attached. Therefore two tasks can be studied: the first one is to estimate the quantity of glue without any ICs where glue is clearly visible while the second one which is more difficult is to infer glue quantity in the case where IC have been attached from the portion of glue that is visible around the ICs. To enable modelling of the measurement noise each PCB is scanned five times, therefore in the dataset there are point clouds for scan_01 up to scan_05 for each circuit module. Also each scan has been performed twice using a 20 micrometer step in measurement and a 50 micrometer step that results in a sparser point cloud. A data augmentation step has been also followed using crops on the x,y axis and adding noise along z. The naming convention that is followed is:pcb_{id of PCB}_scan_{id of scan}_acc_{scanning accuracy}_type_{category of region}_{whether IC has been attached}_circ_{id of circuit}_row_{row on the circuit}_x{augmentation along x}_y{augmentation along y}_z{augmentation along z}.ply.

The annotation files contain the volume of glue for each point cloud corresponsing to a scanned region of a PCB while also indicating the split of the data in a training and a validation set. Concretely for each placeholder type in a circuit module we use the top three for training and the last one for validation. For a detailed explanation of the dataset and the background of the studied problem pleaser refer to "Fault Diagnosis in Microelectronics Attachment via Deep Learning Analysis of 3D Laser Scans" by Dimitriou et al., IEEE Transactions on Industrial Electronics available at: https://doi.org/10.1109/TIE.2019.2931220. For any further questions please contact the dataset author.

Thank you