Datasets

Standard Dataset

A Novel LSTM Pipeline to Detect Anomalies in Manufacturing Production (Datasets)

- Citation Author(s):

- Submitted by:

- James Flynn

- Last updated:

- Mon, 07/08/2024 - 15:59

- DOI:

- 10.21227/e9ew-jn75

- Data Format:

- License:

255 Views

255 Views- Categories:

- Keywords:

Abstract

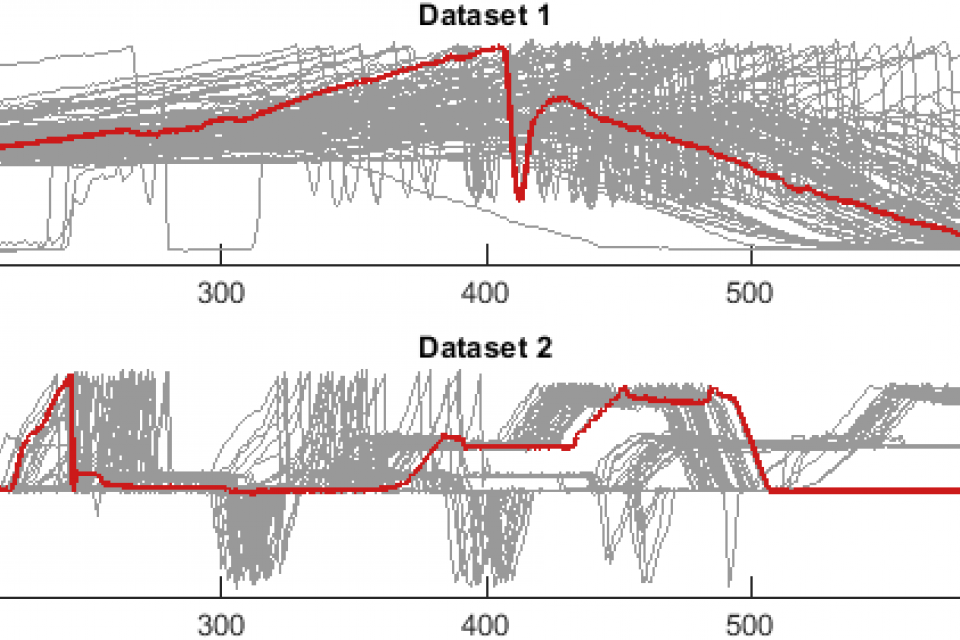

This dataset includes the relevant data for the journal article titled 'A Novel LSTM Pipeline to Detect Anomalies in Manufacturing Production'. In this paper, we present a novel anomaly detection method using a semi-supervised LSTM forecasting approach to highlight process anomalies in a complex, real-world dataset in an automotive manufacturing setting. This data includes two time-series subsets, each with 5000 labeled observations. Both subsets were recorded using an inbuilt torque-time sensor within a DC nut runner tool used to fasten nuts onto various parts throughout the assembly line. The resultant torque time data was labeled by a test engineer and domain expert using the methods outlined in the paper. The labels are denoted in column 1, where 1 = Nominal, 2 = Anomaly No Concern, and -1 = True Anomaly.

This dataset includes the relevant data for the journal article titled 'A Novel LSTM Pipeline to Detect Anomalies in

Manufacturing Production'. In this paper, we present a novel anomaly detection method using a semi-supervised LSTM

forecasting approach to highlight process anomalies in a complex, real-world dataset in an automotive manufacturing

setting. This data includes two time-series subsets, each with 5000 labeled observations. Both subsets were recorded

using an inbuilt torque-time sensor within a DC nut runner tool used to fasten nuts onto various parts throughout the

assembly line. The resultant torque time data was labeled by a test engineer and domain expert using the methods

outlined in the paper.

Labels Key:

1 : Normal Waveform - Waveform appears normal. No action required.

-1 : True Anomaly - Waveform is anomalous and implies some process error has occoured. Action required.

2 : Anomaly No Concern - Waveform is anomalous but upon further inspection no action required.

3 : Rehit - No process has occoured. Repeat process. These can be removed in pre-processing.

Dataset Files

- Test Dataset 1.csv (37.35 MB)

- Test Dataset 2.csv (33.58 MB)

Documentation

| Attachment | Size |

|---|---|

| 1.09 KB |