Datasets & Competitions

Normal 0 0 2 false false false EN-US JA X-NONE /* Style Definitions */ table.MsoNormalTable {mso-style-name:標準の表; mso-tstyle-rowband-size:0; mso-tstyle-colband-size:0; mso-style-noshow:yes; mso-style-priority:99; mso-style-parent:""; mso-padding-alt:0mm 5.4pt 0mm 5.4pt; mso-para-margin:0mm; mso-pagination:widow-orphan; font-size:10.5pt; mso-bidi-font-size:11.0pt; font-family:"游明朝",serif; mso-ascii-font-family:游明朝; mso-ascii-theme-font:minor-latin; mso-fareast-font-family:游明朝; mso-fareast-theme-font:minor-fareast; mso-hansi-font-family:游明朝; mso-hansi-theme-font:minor-latin; mso-font-kerning:

- Categories:

477 Views

477 Views Normal

0

0

2

false

false

false

EN-US

JA

X-NONE

/* Style Definitions */

table.MsoNormalTable

{mso-style-name:標準の表;

mso-tstyle-rowband-size:0;

mso-tstyle-colband-size:0;

mso-style-noshow:yes;

mso-style-priority:99;

mso-style-parent:"";

mso-padding-alt:0mm 5.4pt 0mm 5.4pt;

mso-para-margin:0mm;

mso-pagination:widow-orphan;

font-size:10.0pt;

font-family:"Times New Roman",serif;

mso-fareast-language:EN-US;}

- Categories:

402 Views

402 ViewsAself-moving piezoelectric actuator (SMPA) with high carrying/positioning capability is presented in this article. Its Π-shaped mechanical part comprises four piezo-legs, each of which combines the bending vibrations in the first three orders into the motion in the quasi- sawtooth waveform at the driving foot. Besides, a homemade onboard circuit is integrated with the mechanical part to form compact structure.

- Categories:

69 Views

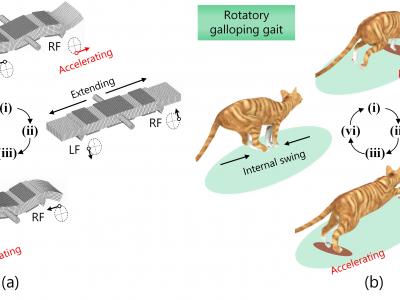

69 ViewsAn untethered ultrasonic robot (U2sonobot) operating in resonant vibration is developed by integrating dual transducers, an onboard circuit, and a battery. Here, the longitudinal and bending vibrations lead to the out-of-phase swing motion and the alternating acceleration, respectively; these imitate the rotatory galloping gait in terms of the driving feet’s movement pattern and the operating sequence. First, the transducers were designed to gather the resonant frequencies of two vibrations and produce the same node for steadily supporting the other components.

- Categories:

94 Views

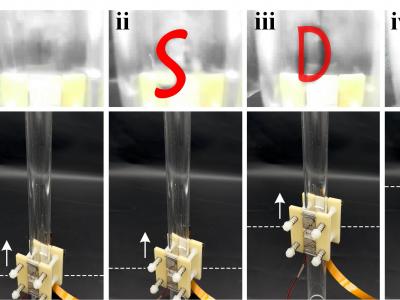

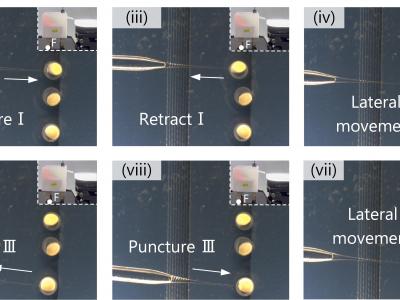

94 ViewsThis figures show a sequence of photos of puncturing into the zerbrafish embryo. Initially, the tip approached the embryo orthogonally to the slot and punctured into the embryo at the instant that it was in contact with the cell membrane. Subsequently, the USPA caused the tip to retract from the embryo; this process changed the embryo’s position possibly because of the dragging force between the pipette and the membrane [48].

- Categories:

40 Views

40 Views(i) At t = nTp [where n is an integer and Tp (= 1/f) is the period], the LF’s longitudinal vibration velocity and bending vibration displacement reach the peak values along the −x and +z axes, respectively.

- Categories:

121 Views

121 Views

Although resonant vibration in the ultrasonic frequency range is thought as a power-intensive way for actuation, its application to untethered miniature mobile robots is still challenging because of lacking the onboard circuit that produces the ultrasonic signals with modulatable frequencies, voltages, and phases. To tackle this problem, first, the ultrasonic transducers whose longitudinal/bending vibrations share a common node was made to steadily support other components. Second, an onboard circuit was designed to convert the battery’s DC signal into multi-channels of ultrasonic signals amplified in a multi-level manner. Third, these components were compactly integrated to developed an untethered ultrasonic robot (U2sonobot) with fast, flexible, and load-carriable movements. The prototype was 54 × 52 × 46 mm3 in size and 76.5 g in weight, and its moving/carrying performance was assessed. At 59.3 kHz frequency, it yielded the maximal speed of 221 mm/s and the minimal step displacement of 0.3 μm. According to the wirelessly-received commands, it produced the flexible movements (e.g., those with adjustable speed/steering-radii and in-situ rotations) and climbed 8.9° slope. Moreover, it carried the maximal payload of 520 g and provided the minimal cost of transport of 3.9. The optical focusing/scanning system is a candidate application area for U2sonobot.

- Categories:

52 Views

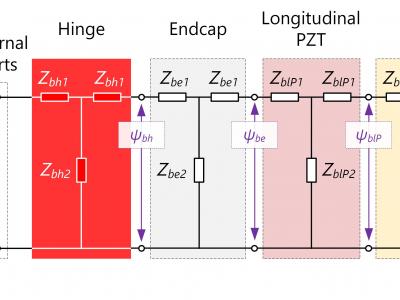

52 ViewsThis appendix discribes how the elements of a Mason-circuit-based dynamic model is formed.

- Categories:

63 Views

63 Views

This video shows a successful case of the transfer robot when our developed method is employed.

The effects of other methods can be found in other videos.

- Categories:

92 Views

92 Views