Real name:

First Name:

AKSHANSH

Last Name:

MISHRA

Affiliation:

Politecnico Di Milano, Milan, Italy

Job Title:

MS Student

Expertise:

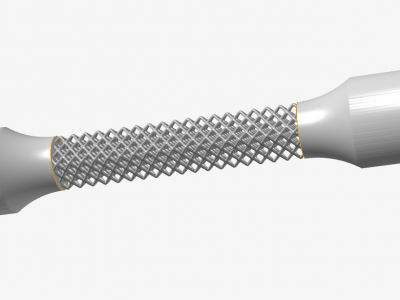

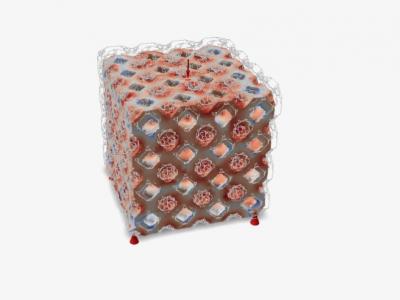

Machine Learning; Advanced Manufacturing

Short Bio:

Akshansh Mishra is currently enrolled as an MS in Materials Engineering student in Politecnico Di Milano. He generally works on the implementation of Artificial Intelligence tools in the domain of manufacturing. His ongoing research projects are synthetic microstructure development of Aluminum-Silicon alloy by using Deep Convolutional Generative Modelling and mechanical properties optimization of Friction Stir Welded joints as well as metal matrix composites.

183 Views

183 Views