Datasets

Standard Dataset

Artificial Intelligence Algorithms for the Analysis of Mechanical Property of Friction Stir Welded Joints by using Python Programming

- Citation Author(s):

- Submitted by:

- AKSHANSH MISHRA

- Last updated:

- Wed, 12/30/2020 - 09:36

- DOI:

- 10.21227/zh9d-5982

- Links:

- License:

420 Views

420 Views- Categories:

Abstract

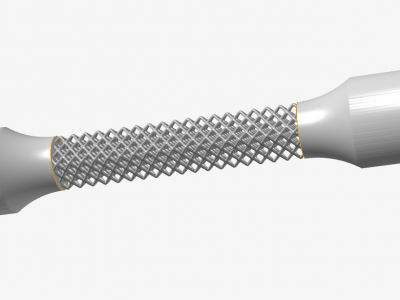

In modern computational science, the interplay existing between machine learning and optimization process marks the most vital developments. Optimization plays an important role in mechanical industries because it leads to reduce in material cost, time consumption and increase in production rate. The recent work focuses on performing the optimization task on Friction Stir Welding process for obtaining the maximum Ultimate Tensile Strength (UTS) of the friction stir welded joints. Two machine learning algorithms i.e. Artificial Neural Network (ANN) and Decision Trees regression model are selected for the purpose. The input variables are Tool Rotational Speed (RPM), Tool Traverse Speed (mm/min) and Axial Force (KN) while the output variable is Ultimate Tensile Strength (MPa). It is observed that in case of the Artificial Neural Networks the Root Mean Square Errors for training and testing sets are 0.842 and 0.808 respectively while in case of Decision Trees regression model, the training and testing sets result Root Mean Square Errors of 11.72 and 14.61. So, it can be concluded that ANN algorithm gives better and accurate result than Decision Tree regression algorithm.

References of the dataset:

- Hema P., Experimental Investigations on AA 6061 Alloy Welded Joints by Friction Stir Welding. In: Cooke KO, editor. Aluminium Alloys and Composites, IntechOpen Limited, 2019. https://doi.org/10.5772/intechopen.89797

- Elatharasan G., Kumar V.S.S., An experimental analysis and optimization of process parameter on friction stir welding of AA 6061-T6 aluminum alloy using RSM. Procedia Engineering, 2013, Vol. 64, 1227–34. https://doi.org/10.1016/j.proeng.2013.09.202

- Netto N., Tiryakioglu M., Eason P., Characterization of Tool Degradation during Friction Stir Processing of 6061-T6 Aluminum Alloy Extrusions. Preprints, 2018, 2018080286. https://doi.org/10.20944/preprints201808.0286.v1

- Amirabadi H., Bani Mostafa Arab N., Safi S.V., A Novel Approach for Improving Mechanical Properties in Friction Stir Butt Welded AA6061 Aluminum Plates by Using Preheat. Preprints, 2020, 2020020183.