A Mechanoluminescent Elastic Resistance Band for Quantitative Resistance Training

- Citation Author(s):

-

Jiawen Liu (Beihang University)

- Submitted by:

- Jiawen Liu

- Last updated:

- DOI:

- 10.21227/acwj-8098

68 views

68 views

- Categories:

- Keywords:

Abstract

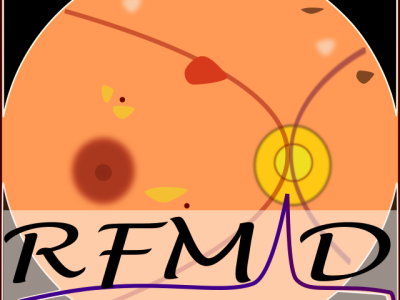

Resistance training with elastic bands has been proven to effectively enhance muscle performance, making it an important component of strength and fitness training. However, assessing the intensity of resistance training typically requires large equipment such as isokinetic dynamometers or complex methods like muscle electromyography. These approaches are highly dependent on professional assistance and cannot be conducted synchronously during training. To solve these problems, we propose a mechanoluminescent elastic resistance band, which just utilizes one monocular vision system to record the deformation of mechanoluminescent elastic resistance, and calculate the force and work people do during training. We first selected a cubic fitting method for the stress-strain mapping relationship taking fitting performance and computing complexity into consideration. The coefficient of determination (R2) and root mean square error (RMSE) of fitting performances were more than 0.999 and about 0.05, respectively. Second, we designed one monocular vision system to detect the dimensions of elastic resistance band which acquired improvements (from 3.66% to 13.92%) to binocular vision system. Third, the mechanoluminescent elastic resistance could generate light when in dynamic stretching or releasing, which could compensate the band detection in different light intensity environment with more than 86.67% detection accuracy. Finally, this quantitative resistance training evaluation system was applied to evaluate different movements, and it could output the force and work trainers did to the band during training. Our study has provided a convenient and effective method for evaluating trainers' resistance training, which is a new way of quantitative resistance training evaluation

Instructions:

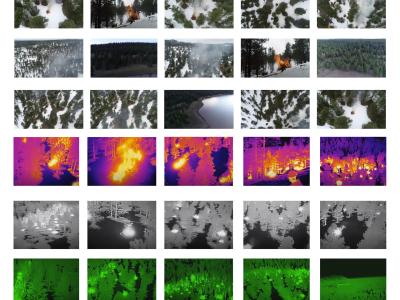

Monocular/binocular vision systems and elastic resistance bands detection

Monocular/binocular vision systems. Vision systems could be divided into two monocular and binocular vision systems according to the adopted cameras in this study. The monocular vision system utilized the width of the feature block was used as a reference dimension to determine the pixel-to-3D world scale, and then the dimension of band could be calculated according to the pixel numbers for each direction. Binocular vision establishes the pixel-to-real-world mapping by calculating the depth map using the SGBM algorithm. Feature information is extracted from images captured by one side of the binocular camera. These images are converted to HSV color space, and the contours of the feature blocks are obtained through a mask. Dimensional measurements were obtained based on the contours in the pixel domain and the pixel-to-real-world mapping relationship. A binocular camera (HBVCAM-4M2214HD-2V11) with a baseline length of 60 cm was used for video acquisition, which could provide two images at each frame. Here, we adopted one image in each frame for the monocular camera system.

Visual experiments for elastic resistance band detection. For the elastic resistance band detection, we mainly focused on detecting the dimension of the key area (i.e. mechanoluminescent film of bands). Visual detection experiments aimed at validating the elastic resistance band detection performances and comparing the performance differences caused by different vision systems (monocular/binocular vision systems). All these are used to make preparations for next trainers’ resistance training.

Elastic resistance bands detection under dynamic stretching and releasing. Research on the static detection of elastic resistance band (i.e. no stress was applied on the band) based on monocular/binocular vision system was essential to ensure precise dimensional measurement in various applications. In addition, the performance differences between monocular and binocular vision systems also needed to be validated. To test the static detection performance, the distance between the camera and the resistance band varied from 20 cm to 120 cm with 20cm increments. During this process, the resistance band was kept facing the monocular/binocular cameras directly. Image data of the resistance band were collected for 5 seconds to analyze the detection results. The angle of the resistance band relative to the camera may change during the training process, thus affecting the recognition results of the visual system. A coordinate system was established based on the center position of the resistance band, and the rotation angle was varied from different directions, with the change range distributed from 0° to 90° with 15° increments. Images were collected for 5 seconds for each setting.

Testing the measurement performance between measured and ground truth under dynamic stretching and releasing conditions was critical for ensuring accurate real-time detection and analysis in applications. In dynamic detection, we designed a series of experiments to analyze the detection performances at different distances, stretching speeds and based on different vision systems. Firstly, dynamic detection experiments were conducted at different distances from 20 cm to 100 cm with 20 cm increments, during which the resistance band was kept facing the camera and he stretching speed was fixed at 400 mm/min. In addition, the dynamic detection was conducted at different stretching speeds (300 mm/min, 400 mm/min and 500 mm/min), while the distance between the resistance band and the camera was fixed at 40 cm. RMSE was adopted as the evaluation metric to illustrate the detection performances for both static and dynamic detection experiments.

Elastic resistance bands detection in low light environment. Mechanoluminescent film could generate light when in dynamic stretch or release state, which could compensate for the light deficiencies. Based on this specific feature, elastic resistance band detection in low-light intensity environments was conducted to verify the effectiveness of mechanoluminescent films. In comparison, another band was fabricated without an integrated mechanoluminescent film. Tensile experiments were conducted in a room with different background illumination intensities which were measured using an illuminance meter (DL333205), and 15 tensile tests were performed under illumination intensity scenarios. Here, we recorded the number that two bands were detected, and calculated the detection accuracy under different light intensities for two bands with and without mechanoluminescent films.