Industrial drying of Filter Media - Moisture Content Prediction

- Citation Author(s):

-

Alexandros Iosifidis (Aarhus University)

- Submitted by:

- Christian Wewer

- Last updated:

- DOI:

- 10.21227/hwa2-tp66

- Data Format:

499 views

499 views

- Categories:

- Keywords:

Abstract

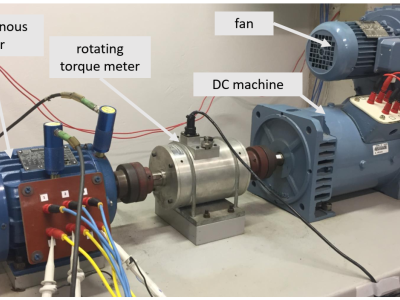

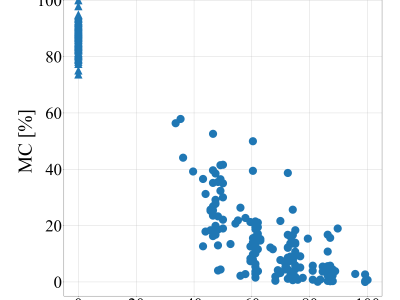

Industrial drying processes are an energy extensive and often one of the most time consuming processes in a manufacturing line. Optimizing the drying process can therefore lead to a reducing in energy consumption and an increase in manufacturing throughput.

Being able to give a reasonable estimate of the moisture content is a catalyst for the optimization process. This dataset consists of 161 different drying experiments of drying filter media in an industrial drying oven, resulting in 322 sets of observations of summarised process parameters as well as snapshots of the current situation inside the oven at the end of each experiment, and the experimentally measured moisture content for that specific time

Instructions:

The dataset consists of 322 rows of 8 features of the drying process. Each feature is individually normalized and multiplied by 100 in order to avoid publishing company secrets.

The 8 features recorded are:

- The drying time measured in minutes. I.e. the number of minutes the filter media has been dried for.

- End temperature. The measured temperature of the filter media.

- Mean oven input temperature. A summarised value, describing the mean temperature that the filter media has experienced during drying.

- Mean blower differentrial pressure. A summarised value, describing the mean differential pressure across the blower of the oven for the duration that the filter media was inside the oven.

- Oven inlet end temperature. The temperature of the hot inlet air.

- initial mass. The initial mass of the filter media before drying begun. initial mass is thus the sum of the solid mass and moisture mass.

- Oven chamber position. Which one of the 4 positions inside the oven the filter media was situated at.

- End moisture content. The moisture content at the time of measuring.