Fuzzy-PID-Based Frequency-Tracking Technique for Ultrasonic Vibration Systems

- Citation Author(s):

- Submitted by:

- Li-Yang Kong

- Last updated:

- DOI:

- 10.21227/H2WW9S

317 views

317 views

- Categories:

- Keywords:

Abstract

When heterogeneous honeycomb materials are cut using ultrasonic techniques, the ultrasonic frequency tends to vary over time, thereby degrading the quality of the machining. This variation can be addressed with a proportional–integral–derivative (PID) controller; however, these controllers perform relatively poorly in fixed parameter tracking scenarios. In contrast, this paper proposes a tracking model that combines fuzzy and PID control. Data describing the changes in the phase difference at the two ends of the ultrasonic vibration system when cutting honeycomb materials was analyzed to identify the necessary support and demand indicators required to establish the model. Based on the PID control model, fuzzy control rules were introduced and appropriate frequency tracking steps were developed. Then, the principles of fuzzy control and the phase difference data were applied to establish rules for a fuzzy–PID frequency tracking model. The developed models were validated by simulation and experiment. Based on the results of this study, the proposed method increases the accuracy of ultrasonic frequency tracking, which makes it suitable for application in more severe working environments.

Instructions:

Figure 1 is screenshots of the measuring instrument for phase change during ultrasonic machining of cellular materials measured by NI acquisition card;

Table 1, Table 2, and Table 3 are control parameter settings for fuzzy PID control;

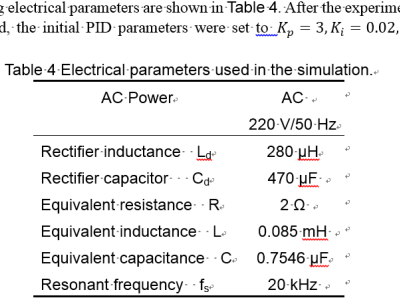

Table 4 shows the impedance parameters selected during the experiment and the initial control parameter settings;

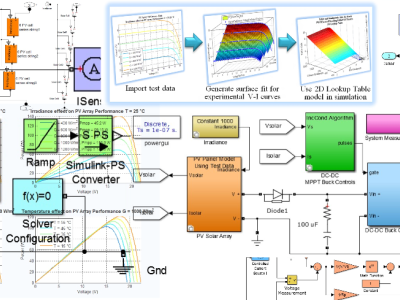

Figure 7 shows the simulation of frequency tracking under different control methodsg;

Fig. 8 and Fig. 9 are screenshots of the measuring instrument for the phase difference effect of tracking modules at different frequencies during actual machining.

There is not much raw data, mostly screenshots of testing instruments, and specific parameter values of experimental equipment