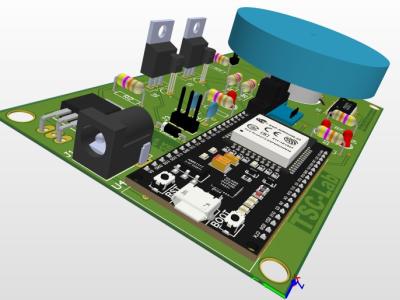

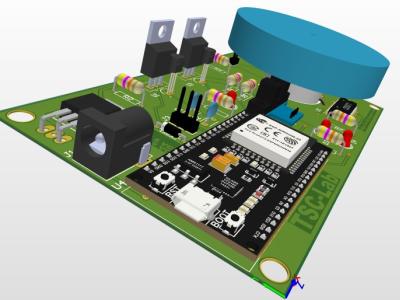

2 PHASE ENERGY METER 100A (2PEM-100A)

- Submission Dates:

-

to

- Citation Author(s):

-

Ronald Reyes (Ecuaplus)

- Submitted by:

- Victor Asanza

- Last updated:

- DOI:

- 10.21227/6f3r-t917

- Data Format:

- Links:

- Categories:

- Keywords:

Abstract

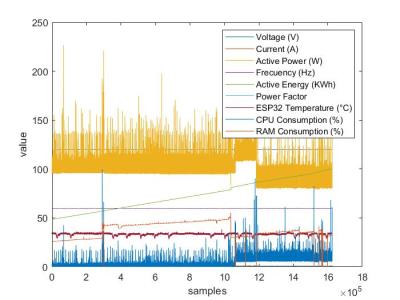

The 2 PHASE ENERGY METER 100A (2PEM-100A) is a power consumption monitor based on an embedded system. In the hope of promoting responsible energy consumption, we have decided to release this open source hardware project that was developed in the course "Development of Electronic Prototypes" at the ESPOL University. The 2PEM-100A allows to monitor the following parameters: Voltage (V), Current (A), Power (W), Frequency (Hz), Energy (KWh), Power Factor and Temperature (°C) of the 2PEM-100A.

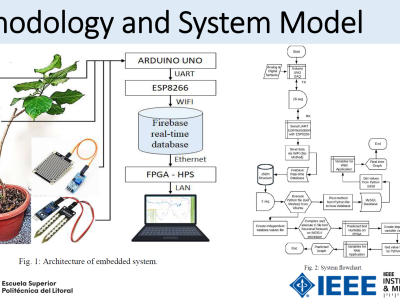

This dataset includes the monitoring of energy consumption of a Data Server that is working in the facilities of the Information Technology Center (CTI) of the Escuela Superior Politecnica del Litoral (ESPOL). The data acquisition equipment was 2PEM-100A. 2PEM-100A is open-source hardware based on the ESP32 hardware.

Open hardware Certification:

Link of 2 PHASE ENERGY METER 100A (2PEM-100A):

Related scientific publications:

- V. Asanza, R. E. Pico, D. Torres, S. Santillan and J. Cadena, "FPGA Based Meteorological Monitoring Station," 2021 IEEE Sensors Applications Symposium (SAS), 2021, pp. 1-6, doi: 10.1109/SAS51076.2021.9530151.

- Asanza V., Sanchez G., Cajo R., Peláez E. (2021) Behavioral Signal Processing with Machine Learning Based on FPGA. In: Botto-Tobar M., Zamora W., Larrea Plúa J., Bazurto Roldan J., Santamaría Philco A. (eds) Systems and Information Sciences. ICCIS 2020. Advances in Intelligent Systems and Computing, vol 1273. Springer, Cham. https://doi.org/10.1007/978-3-030-59194-6_17

- V. A. Armijos, N. S. Chan, R. Saquicela and L. M. Lopez, "Monitoring of system memory usage embedded in FPGA," 2020 International Conference on Applied Electronics (AE), Pilsen, Czech Republic, 2020, pp. 1-4, doi: 10.23919/AE49394.2020.9232863

More related repositories:

Instructions:

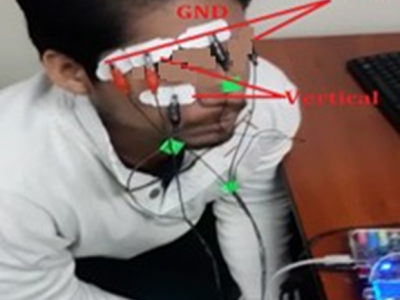

The equipment used to perform these measurements was 2PEM-100A (https://2pem100a.blogspot.com/). The steps that were performed in the installation of the equipment 2PEM-100A for the recording of these data are available at the following link (Electrical Installation and Connections), as follows:

- Remove the cover of MCB-100A

- Remove the Jumper

- Conectar el Cable USB a un Computador

- Connecting the measuring coils

- Staple the coils to the load lines.

- Energizing the MCB-100A

- Install ARDUINO IDE on the Computer

The data set includes 12 days of power consumption log at a sampling rate of 4 data per second (4Hz). The columns represent the following variables:

- Voltaje (V)

- Current (A)

- Power (W)

- Frecuency (Hz)

- Energy (KWh)

- Power Factor

- Temperature ESP32 (°C)

- CPU usage (%)

- RAM usage (%)

To use the attached data (dataset.mat), please follow the step-by-step instructions described in the attached PDF files:

Source code used to program the measuring equipment (2PEM-100A):

Design of the printed circuit board (PCB) of the measuring equipment (2PEM-100A):

Data processing codes using Matlab:

More examples using dataset:

- Practice 0: Installation of support programming #ESP32

- Practice 1: Introduction to the PZEM004T sensor

- Practice 2: Storage of measurements in Excel file

- Practice 3: Mostrar Datos via Internet

- Practice 4: Mostrar Datos via web desde una red creada

- Practice 5: Medicion Bifasica utilizando Sensores PZEM004T

- Practice 6: Envio Datos a #ThingSpeak

In reply to Data pre-processing by Veronica Ojeda

In reply to Question by Kevin Chica

In reply to Connection failure by Galo Sanchez

In reply to cloud storage by Guillermo Mont…

In reply to Device Quality by John Rivera

In reply to Question by Daniel Montoya…

In reply to Is there any repository with by Jonathan Cagua…

In reply to Real Time Alert by Israel Jimenez

In reply to Predictive model capabilities by Anthony Maisincho

In reply to Reinforced Learning Control by Christian Castillo