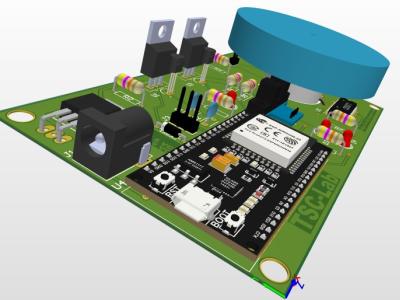

Temperature and Speed Control Lab (TSC-Lab)

- Citation Author(s):

-

César Martín (Escuela Superior Politécnica del Litoral, ESPOL)

- Submitted by:

- Victor Asanza

- Last updated:

- DOI:

- 10.21227/8cty-6069

- Data Format:

- Links:

98914 views

98914 views

- Categories:

- Keywords:

Abstract

This is an initiative developed by FIEC-ESPOL professors. Temperature and Speed Control Lab (TSC-LAB) is an open source hardware development.

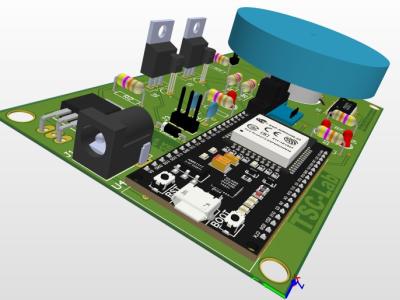

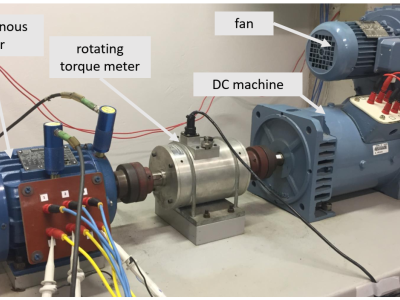

The Temperature and Speed Control Lab (TSC-Lab) is an application of feedback control with an ESP32, an LED, two heaters, two temperature sensors, one direct current motor and an optical encoder as a revolution per minute (rpm) meter. The heater power output is adjusted to maintain the desired temperature setpoint. Thermal energy from the heater is transferred by conduction, convection, and radiation to the temperature sensor. Heat is also transferred away from the device to the surroundings. On the other hand, the motor speed is adjusted using a motor driver and with PWM signals, allowing the reference speed to be reached using the rpm meter.

Open Hardware Certification:

The practice guides that were used in the data acquisition process are detailed in the following blog:

The codes used are in the following repository:

References:

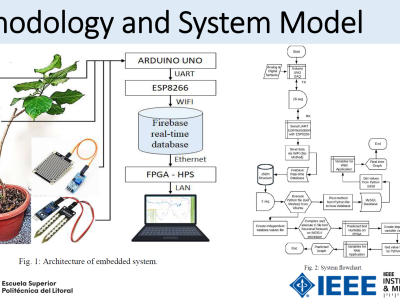

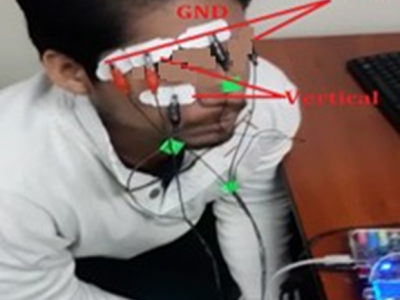

- Asanza V., Sanchez G., Cajo R., Peláez E. (2021) Behavioral Signal Processing with Machine Learning Based on FPGA. In: Botto-Tobar M., Zamora W., Larrea Plúa J., Bazurto Roldan J., Santamaría Philco A. (eds) Systems and Information Sciences. ICCIS 2020. Advances in Intelligent Systems and Computing, vol 1273. Springer, Cham. https://doi.org/10.1007/978-3-030-59194-6_17

- Asanza, V., Martín, C. A., Eslambolchilar, P., van Woerden, H., Cajo, R., & Salazar, C. (2017, October). Finding a dynamical model of a social norm physical activity intervention. In Ecuador Technical Chapters Meeting (ETCM), 2017 IEEE (pp. 1-6). IEEE

- C. Angel Silva, V. Asanza, N. Sánchez and J. Arias, "Implementation Of Automated System For The Reservoir 66 of the Irrigation System Chambo Guano," 2020 International Conference on Applied Electronics (AE), Pilsen, Czech Republic, 2020, pp. 1-6, doi: 10.23919/AE49394.2020.9232888

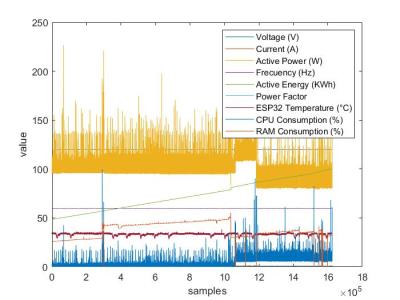

- V. A. Armijos, N. S. Chan, R. Saquicela and L. M. Lopez, "Monitoring of system memory usage embedded in FPGA," 2020 International Conference on Applied Electronics (AE), Pilsen, Czech Republic, 2020, pp. 1-4, doi: 10.23919/AE49394.2020.9232863

Instructions:

The files must be downloaded and placed in the same folder so that they can be compiled in MATLAB, remember that these data were obtained in open loop for their respective identification of this system.

Temperature plant data:

- In any data "dato.csv" the first column represents the temperature acquired by sensor 1, the second column the temperature acquired by sensor 2, third and fourth column represent the state of activation (1) or deactivation (0) of transistor 1 and 2, respectively.

DC motor speed plant data:

- The motor speed control plant allows the engine RPM to be measured with the help of an optical echoder. The speed and direction of the motor is controlled through a motodriver.

Source code: