Datasets

Open Access

Cold forging process failures

- Citation Author(s):

- Submitted by:

- Haw-Ching Yang

- Last updated:

- Wed, 11/04/2020 - 19:43

- DOI:

- 10.21227/rpdg-wv37

- Data Format:

- License:

572 Views

572 Views- Categories:

- Keywords:

1 rating - Please login to submit your rating.

Abstract

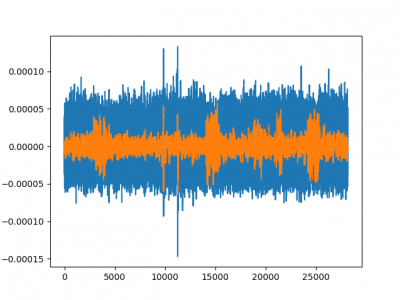

When producing bolts in a cold forging process, the pressure signals are recorded per cycle of forming a bolt. The dataset is collected from experiments of different failure modes of a forming machine. Two experiments were recorded in csv format for providing four failure modes, including core broken, cavity block, insufficient lubrication, and material out-of-specification, as well as one normal mode. The two experiments were performed in the same machine with different cavities and cores, and saved in Experimental Data for Modeling and Testing.

Instructions:

- Domain: cold bolt forging process

- source: pressure sensor

- Sampling rate: 1000 Hz

- Target: failure classification

- Failure modes:

- 1. Normal: normal production.

- 2. Cavity Block: a cavity was blocked with different heights of bumps.

- 3. Core Broken: a core being broken into three levels

- 4. Insufficient Lubrication: insufficient lubrication in two levels.

- 5. Material out-of-specification: the materials being shorter or longer.

- Total files: 2

- File format: csv

- Description of fields in each file

- TimeTag: experimental recording time of each producing cycle.

- Label: faliure mode

- Rawdata1-Rawdata386: pressure data collected by each bolt forming in a sampling rate 1000 Hz. 1-386 means it takes 0.386 sec to finish a bolt forming cycle, and their values stand for the raw data without standardization.

Dataset Files

Experimental Data for Modeling Forming Failure Exp1.csv (2.01 MB)

Experimental Data for Testing Forming Failure Exp2.csv (2.56 MB)

Open Access dataset files are accessible to all logged in users. Don't have a login? Create a free IEEE account. IEEE Membership is not required.