Additive Manufacturing Processes Protocol Prediction by Artificial Intelligence using X-ray Computed Tomography data

- Citation Author(s):

-

Mayank GoswamiSunita Khod

- Submitted by:

- mayank goswami

- Last updated:

- DOI:

- 10.21227/byk9-sh39

176 views

176 views

- Categories:

- Keywords:

Abstract

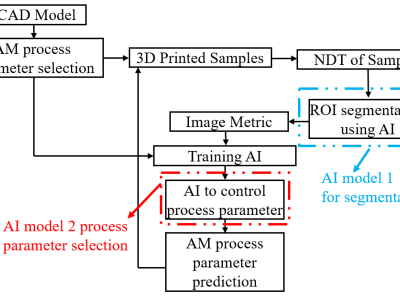

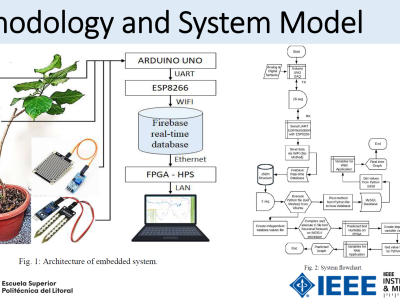

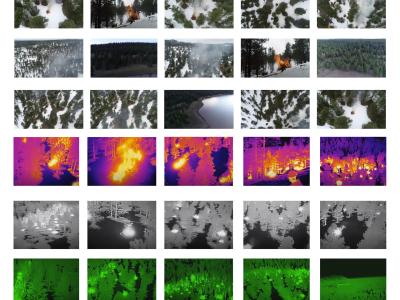

This study includes three commercially available 3D printers for soft material printing based on the Material Extrusion (MEX) AM process. The samples are 3D printed for six different AM process parameters obtained by varying layer height and nozzle speed. The novelty part of the methodology is incorporating an AI-based image segmentation step in the decision-making stage that uses quality inspected training data from the Non-Destructive Testing (NDT) method.The performance of the trained AI model is compared with the two software tools based on the classical thresholding method. The AI-based Artificial Neural Network (ANN) model is trained from NDT-assessed and AI-segmented data to automate the selection of optimized process parameters.

The AI-based model is 99.3 % accurate, while the best available commercial classical image method is 83.44 % accurate. The best value of overall R for training ANN is 0.82. The MEX process gives a 22.06 % porosity error relative to the design. The NDT-data trained two AI models integrated into a series pipeline for optimal process parameters are proposed and verified by classical optimization and mechanical testing methods.

Instructions:

Please download the file, unzip, and the data contains all the codes and data.

The artificial intelligence driven models trained with NDT data are proposed for optimal process protocol for additive manufacturing.