Vision and Acoustic Emission Dataset

- Citation Author(s):

-

Ruiyao HuangKang Liu

- Submitted by:

- Ruiyao Huang

- Last updated:

- DOI:

- 10.21227/2bmw-cn91

21 views

21 views

- Categories:

- Keywords:

Abstract

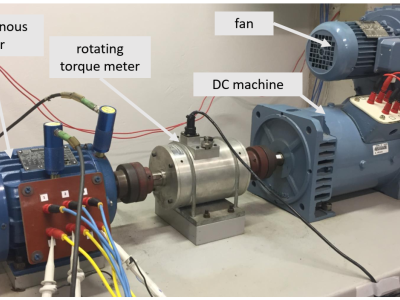

The diameter of the rivet hole is 5mm. In the experiments at the Cooperative Institute, the AE sensor spacing was set to 130mm, where the centers of sensor 1 and sensor 2 were 90mm from each end of the test piece. The waveform flow data obtained in the experiment only retained the information from 30 minutes before the crack initiation to the fracture of the test piece, and the image data of the test piece during this period were recorded. The loading conditions were in the form of sinusoidal curves with a maximum load of 17kN and a minimum load of 1.7kN, a frequency of 5Hz, a gripping force of 90bar.

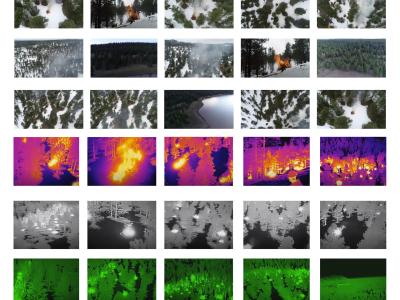

A crack appeared on the right side of the opening of the test piece. The test started at 9:32, and the experimental process experienced several pauses and continuations, including acoustic emission acquisition and zeroing of the test machine, etc. The crack length and the number of cycles were recorded. The test piece began to crack 11 hours and 25 minutes after the start of the experiment, and broke 1 hour and 1 minute after the crack appeared, and the number of cycles at the time of fracture was 86,510. A total of 1795 images were recorded, including 755 defect-free images and 1040 defective images. After removing the data from the zeroing process of the tester, a total of 1755 aircraft crack image datasets were formed. This dataset was meticulously categorized into 715 non-defective images and 1040 defective images. Each image has a high resolution of 5472×3648 pixels, enabling the capture of fine-grained details. Significantly, these images cover the entire spectrum of the crack development process, from the initial stage of crack initiation to the final stage of specimen fracture. It provides a sequential visual representation of how cracks progress over time, facilitating in-depth analysis of crack-related features at different stages.

Instructions:

Label the picture, and use AEwin software to decode the DTA format file to get a series of data processing after the file.