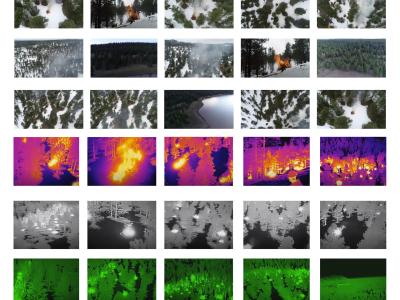

Thermal Images with different amount of contaminats on the lens

- Citation Author(s):

-

Vittoria Medici

- Submitted by:

- Vittoria Medici

- Last updated:

- DOI:

- 10.21227/s9he-yx37

88 views

88 views

- Categories:

- Keywords:

Abstract

The paper assesses the effectiveness of sharpness metrics for monitoring the cleanliness of in-line thermographic systems and enabling self-diagnosis, in order to prevent degradation of metrologic performance and increase of measurement uncertainty. When optical measurement systems are installed in harsh industrial environments, external contaminants may compromise their operation conditions. Various types of dust may settle on the lens or protective window, deteriorating the quality of the generated signal. Particularly, when the observed object is at very high temperatures, the thermal image produced by a thermographic inspection system loses sharpness, making it difficult to identify object edges and decreasing the output data quality. Monitoring image sharpness over time helps maintain system cleanliness and ensure the quality of the generated data. The effectiveness of blur metrics, commonly employed to assess proper focus or the quality of images of moving objects, is evaluated to understand if image quality has deteriorated due to external contaminants. The metrics judged best were applied to data from a real industrial case to confirm their efficacy.

Instructions:

The dataset is composed of two set of images: one for a circular steel plate and one for a squared steel plate.

They are composed of thermal images, which are temperature matrix, as the amout of contaminants on the lens of the thermal camera increases.

They are used to evaluate how sharpness metrics changes as the amount of contaminats increase.

For each amount of contaminats, five images have been acquired,