Files to build autosampler

- Citation Author(s):

- Submitted by:

- Ruchi Gupta

- Last updated:

- DOI:

- 10.21227/402w-8s89

- Data Format:

- Research Article Link:

176 views

176 views

- Categories:

- Keywords:

Abstract

Normal 0 false false false EN-GB X-NONE X-NONE /* Style Definitions */ table.MsoNormalTable {mso-style-name:"Table Normal"; mso-tstyle-rowband-size:0; mso-tstyle-colband-size:0; mso-style-noshow:yes; mso-style-priority:99; mso-style-parent:""; mso-padding-alt:0cm 5.4pt 0cm 5.4pt; mso-para-margin-top:0cm; mso-para-margin-right:0cm; mso-para-margin-bottom:8.0pt; mso-para-margin-left:0cm; line-height:107%; mso-pagination:widow-orphan; font-size:11.0pt; font-family:"Calibri",sans-serif; mso-ascii-font-family:Calibri; mso-ascii-theme-font:minor-latin; mso-hansi-font-family:Calibri; mso-hansi-theme-font:minor-latin; mso-bidi-font-family:"Times New Roman"; mso-bidi-theme-font:minor-bidi; mso-fareast-language:EN-US;}

Normal 0 false false false EN-GB X-NONE X-NONE /* Style Definitions */ table.MsoNormalTable {mso-style-name:"Table Normal"; mso-tstyle-rowband-size:0; mso-tstyle-colband-size:0; mso-style-noshow:yes; mso-style-priority:99; mso-style-parent:""; mso-padding-alt:0cm 5.4pt 0cm 5.4pt; mso-para-margin-top:0cm; mso-para-margin-right:0cm; mso-para-margin-bottom:8.0pt; mso-para-margin-left:0cm; line-height:107%; mso-pagination:widow-orphan; font-size:11.0pt; font-family:"Calibri",sans-serif; mso-ascii-font-family:Calibri; mso-ascii-theme-font:minor-latin; mso-hansi-font-family:Calibri; mso-hansi-theme-font:minor-latin; mso-bidi-font-family:"Times New Roman"; mso-bidi-theme-font:minor-bidi; mso-fareast-language:EN-US;}

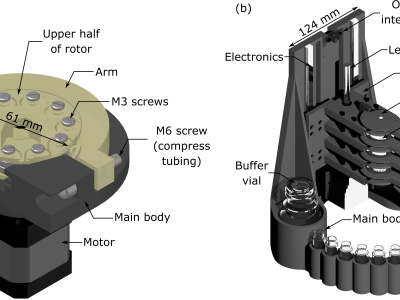

Automation of fluid manipulation is needed to increase throughput and reproducibility of experiments while reducing the time spent by researchers on performing repetitive tasks. Current solutions are however bulky and expensive, and hence not suited to enable automation in academic laboratories. This work therefore reports a low cost, modular and programmable analytical platform comprising of 3D printed autosampler and peristaltic pump with footprints of 248 mm by 243 mm and 104 mm by 112 mm, respectively. The autosampler consisted of four samples probes/needles that can be driven independently to any of the available solution vials placed along the circumference of a circle. The 3D printed autosampler developed in this work can access higher number of solution vials independently and is lower cost, but accommodates fewer number of total solution vials, than commercial devices. The autosampler and peristaltic pump were applied to determine (1) refractive index sensitivity, (2) porosity, and (3) sensing capability of leaky waveguides (LWs) where the read-out instrument was also 3D printed. We demonstrated that the automation of fluids enabled by the analytical platform improved the accuracy of results by separating the effect of temperature drifts from analyte solutions from the output of LWs. This work shows that 3D printed instrumentation can provide results comparable with standard laboratory versions at much lower cost, making it ideal for use in resource-limited settings, and with the possibility of customization as experimental needs change.

Normal 0 false false false EN-GB X-NONE X-NONE /* Style Definitions */ table.MsoNormalTable {mso-style-name:"Table Normal"; mso-tstyle-rowband-size:0; mso-tstyle-colband-size:0; mso-style-noshow:yes; mso-style-priority:99; mso-style-parent:""; mso-padding-alt:0cm 5.4pt 0cm 5.4pt; mso-para-margin-top:0cm; mso-para-margin-right:0cm; mso-para-margin-bottom:8.0pt; mso-para-margin-left:0cm; line-height:107%; mso-pagination:widow-orphan; font-size:11.0pt; font-family:"Calibri",sans-serif; mso-ascii-font-family:Calibri; mso-ascii-theme-font:minor-latin; mso-hansi-font-family:Calibri; mso-hansi-theme-font:minor-latin; mso-bidi-font-family:"Times New Roman"; mso-bidi-theme-font:minor-bidi; mso-fareast-language:EN-US;}

Instructions:

These are the design files for the hardware and software of the printed instrument are contained in three zip archives.

Autosampler design files.zip - IGS and STEP files of all the printed parts of the instrument, and bill of materials for pump and autosampler

Autosampler PCB.zip - Gerbers, schematic and bill of materials for the PCB

Autosampler Software.zip - Software for the ARM processor and PC running the instrument

To compile the code for the ARM processor, the STM32CubeIDE integrated development environment must be downloaded and installed from:

https://www.st.com/en/development-tools/stm32cubeide.html

The PC software is supplied as a precompiled 32-bit Windows executable. It does not need to be installed.

The design and software is free for non-commercial use, but this work should be cited if use or modification is made of the design.

Normal 0 false false false EN-GB X-NONE X-NONE /* Style Definitions */ table.MsoNormalTable {mso-style-name:"Table Normal"; mso-tstyle-rowband-size:0; mso-tstyle-colband-size:0; mso-style-noshow:yes; mso-style-priority:99; mso-style-parent:""; mso-padding-alt:0cm 5.4pt 0cm 5.4pt; mso-para-margin-top:0cm; mso-para-margin-right:0cm; mso-para-margin-bottom:8.0pt; mso-para-margin-left:0cm; line-height:107%; mso-pagination:widow-orphan; font-size:11.0pt; font-family:"Calibri",sans-serif; mso-ascii-font-family:Calibri; mso-ascii-theme-font:minor-latin; mso-hansi-font-family:Calibri; mso-hansi-theme-font:minor-latin; mso-bidi-font-family:"Times New Roman"; mso-bidi-theme-font:minor-bidi; mso-fareast-language:EN-US;}