Design, Analysis and Control of a Low Speed and High Torque Five-phase External Rotor Permanent Magnet Machine for Direct Drive Application

- Citation Author(s):

-

Jinlin Gong

- Submitted by:

- Jinlin GONG

- Last updated:

- DOI:

- 10.21227/yrt9-8k34

254 views

254 views

- Categories:

- Keywords:

Abstract

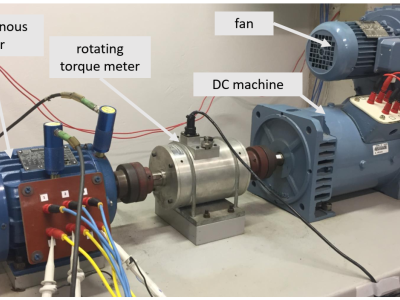

This paper presents the design, analysis and control of an original low speed and high torque five-phase external rotor permanent magnet synchronous machine (PMSM) applied for the direct drive of coal conveying system. Firstly, the design considerations including the windings factors and the magnetomotive force (MMF) are given. Secondly, according to the performance requirements, the preliminary dimensions of the machine are firstly calculated using the magnetic circuit method, and then optimized using a Kriging model optimization strategy. Thirdly, the performances of the proposed five-phase PMSM are given and compared to a traditional three-phase PMSM, including both the no-load and on-load conditions using finite element method (FEM). An increase of 22.3% for the output torque with same copper losses is found. Keeping low torque ripples, the torque density of the five-phase machine can be still improved by 14.6% by injection of third harmonic current with same resultant peak current. Finally, a 5-phase, 40-slot, 44-pole prototype is fabricated, and the expected performance of the prototype is analyzed through experiments.

Instructions:

This paper presents the design, analysis and control of an original low speed and high torque five-phase external rotor permanent magnet synchronous machine (PMSM) applied for the direct drive of coal conveying system. Firstly, the design considerations including the windings factors and the magnetomotive force (MMF) are given. Secondly, according to the performance requirements, the preliminary dimensions of the machine are firstly calculated using the magnetic circuit method, and then optimized using a Kriging model optimization strategy. Thirdly, the performances of the proposed five-phase PMSM are given and compared to a traditional three-phase PMSM, including both the no-load and on-load conditions using finite element method (FEM). An increase of 22.3% for the output torque with same copper losses is found. Keeping low torque ripples, the torque density of the five-phase machine can be still improved by 14.6% by injection of third harmonic current with same resultant peak current. Finally, a 5-phase, 40-slot, 44-pole prototype is fabricated, and the expected performance of the prototype is analyzed through experiments.