Datasets

Standard Dataset

Additive Manufactured Inconel-625 with FEM - Averaged Nodes

- Citation Author(s):

- Submitted by:

- Jason Hasse

- Last updated:

- Thu, 06/13/2024 - 15:31

- DOI:

- 10.21227/ffx6-n533

- Data Format:

- License:

140 Views

140 Views- Categories:

- Keywords:

Abstract

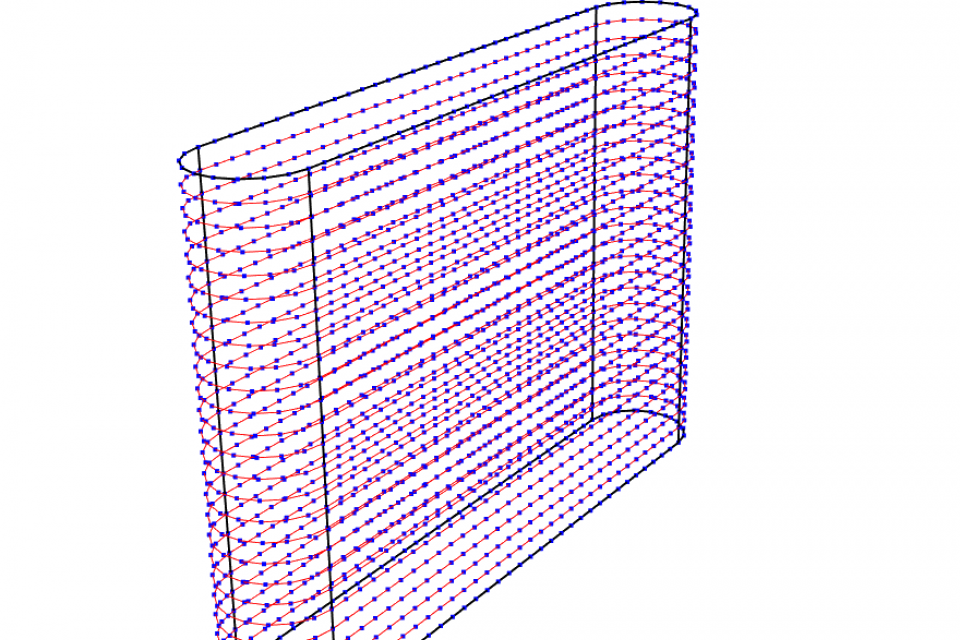

This dataset contains simulation values from thermo-mechanical finite element analysis simulations using ABAQUS. Each simulation is one of 192 unique process parameter settings which includes varying laser power, scan speed, layer height and cooling assumptions. The geometry for each simulation is a hollow rectangluar box with rounded corners such that they form semi-circles. The wall thickness of each simulation is exactly the width of the focused laser. This dataset is the result of using nearest neighbor averaging from the original 818,688 nodes into 18,816 nodes to allow for the use of iterative algorithms while keeping the accuracy high for the finite element simulation. The averaging scheme is meant to keep the broad structural properties intact.

The primary goal with the dataset is to use the process parameters (labelled in the data dictionary) to predict response of either von Mises stress or the total displacement. The authors of the dataset choose to use mixture modeling techniques to get these predictions and for inference about how the process parameters influence the response.

Documentation

| Attachment | Size |

|---|---|

| 3.6 KB |