Datasets

Open Access

Using deep learning edge detection to improve non-destructive radiographic tests of engine

- Citation Author(s):

- Submitted by:

- Zhihao Chen

- Last updated:

- Wed, 07/08/2020 - 16:08

- DOI:

- 10.21227/wwq3-7q68

- Data Format:

- License:

1832 Views

1832 Views- Categories:

- Keywords:

Abstract

This paper aims to improve the existing techniques on X-ray image inspection of aerial engine by using artificial intelligence (AI) based object detection model. This technique seeks to augment and improve existing automated non-destructive testing (NDT) diagnosis of metal structure of engine parts. Traditional jet-engine maintenance and overhaul processes are resorted to NDT to find defects in internal welds. An application of deep learning for NDT technology can effectively identify presence and location of up to eight types of defects, leading to enhanced work quality and efficiency. The finer object detection of image feature maps will lead to more accurate identification of weld flaws than can be accomplished by the standard visual examination. The proposed approach adopts a region-based convolutional neural network and a deep learning neural network for object detection to render an efficient X-ray image diagnosis system. The approach may benefit the inspection work in the aviation industry via increased accuracy and efficiency.

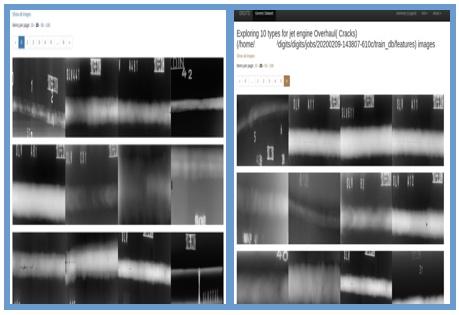

This tool model propose use deep learning edge detection to improve non-destructive radiographic tests of engine cracks by employing in deep unsupervised learning on RT architecture. he engine repair plant has accumulated a data gallery of X-ray images. In the dataset, defects in engine can be categorized as either (a) cracks, (b) incomplete fusion, (c) incomplete penetration, (d) porosity, (e) slag inclusion, (f) undercut, (g) welding spatter, or (h) blowhole as depicted in Figure 4. The X-ray images in the dataset are converted into LMDB format and stored for deep learning application. In the dataset, some X-ray images in different light conditions and resolutions have been labeled with the above defects. An effort is made to prepare the labeled data in terms of DetectNet model. In this endeavor, the 8 types of label classes are stored in the first row of the category table string over 6,000 labeled X-ray images dataset.

More from this Author

Dataset Files

20200430-162114-d447_epoch_600.0.zip (21.55 MB)

Access_2020_16392_Dataset_SCRIPTS.pdf.zip (35.78 kB)

Open Access dataset files are accessible to all logged in users. Don't have a login? Create a free IEEE account. IEEE Membership is not required.

Documentation

| Attachment | Size |

|---|---|

| 37.56 KB |

Comments

I am a new postgraduate from the department of Computer Science in SHU,China.I am finding the dataset for my study.

hello , how can i get access to the data because i am not seeing a link to access/download it ?

Thanks

Hello, did somebody succeed accessing the dataset? I am wondering how to get access to the dataset after subscription?

I am unable to find the images in any of the zip files attached. Anybody able to help?

Thanks.

hi, i need to download the data