Datasets

Open Access

Experimental Comparison of Optical Inline 3D Measurement and Inspection Systems

- Citation Author(s):

- Submitted by:

- Lukas Traxler

- Last updated:

- Tue, 05/17/2022 - 22:21

- DOI:

- 10.21227/j9x0-g074

- Data Format:

- Link to Paper:

- Links:

- License:

340 Views

340 Views- Categories:

- Keywords:

Abstract

Fast optical 3D inline inspection sensors are a powerful tool to advance factory automation. Many of these visual inspection tasks require high speeds, resolutions and repeatability. Different approaches exist. Stereo vision, photometric stereo, light sectioning and structured light are the most common principles for inline imaging in the several micrometers to sub-millimeter resolution range. Selecting the correct sensor principle can be challenging as manufacturers’ datasheets frequently use different values to describe their systems and do not stick to proposed characterizations defined by the „Initiative Fair Data Sheet" or the VDE/VDI standards. With the help of standardized parameters this paper aims to compare four different measurement principles, namely an in-house developed single sensor light field camera, a structured light pattern projection, a laser triangulation sensor and a stereo-camera system. We demonstrate simple yet meaningful experiments to determine optical resolution, temporal noise and calibration accuracy for an objective system comparison. Additionally, the reproduction of small surface structures and an overall performance on a challenging test object is evaluated. Results show that the measurement principles partly serve different application areas. The provided methods will help end users to select the correct sensor for specific applications.

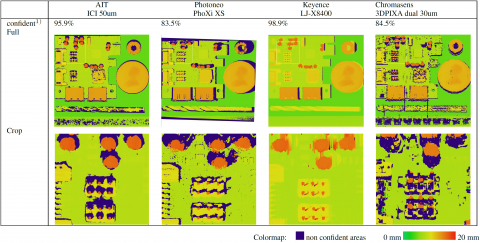

We compared different optical inline 3D measurement systems. Quantitative results are presented in our paper (Table 3). For a qualitative comparison we acquired the same artificial scene with al tested systems. The results are presented in this dataset.

System 1: testobjekt_lightfield_ICI-50um.ply

System 2: testobjekt_strucrued_light_PhoXi-XS.ply

System 3: testobjekt_laser_triangualtion_LJ-X8400.ply

System 4: System: testobjekt_3DPIXA-30um.ply

Dataset Files

pointclouds.zip (152.77 MB)

Open Access dataset files are accessible to all logged in users. Don't have a login? Create a free IEEE account. IEEE Membership is not required.