Datasets

Standard Dataset

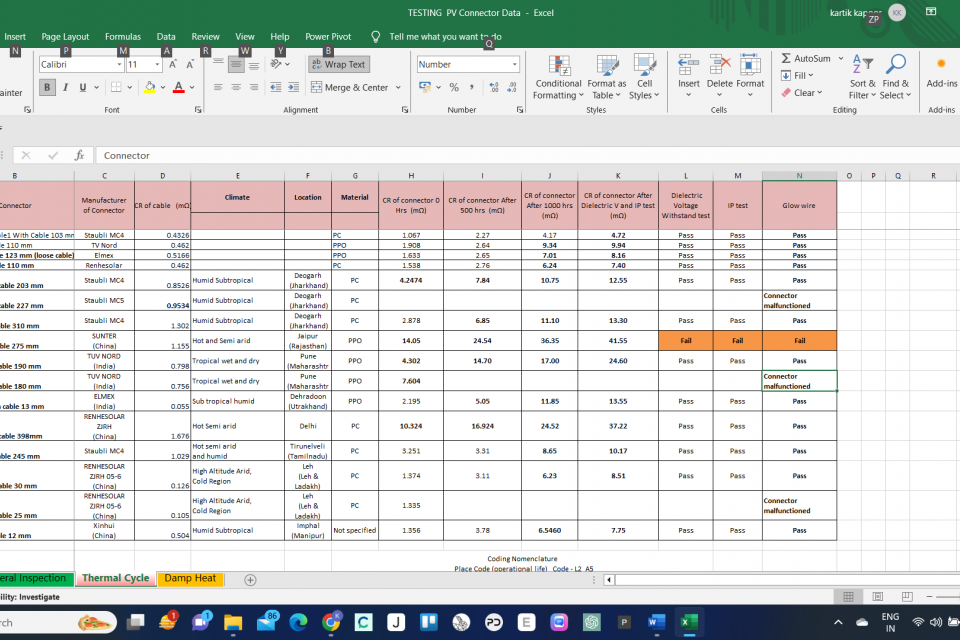

TESTING PV CONNECTOR DATA

- Citation Author(s):

- Submitted by:

- kartik kapoor

- Last updated:

- Mon, 11/04/2024 - 14:34

- DOI:

- 10.21227/v12r-5j02

- Data Format:

- License:

39 Views

39 Views- Categories:

- Keywords:

Abstract

The paper presents the reliability study on field-aged photovoltaic connectors of different makes, collected from solar PV plants situated in different regions across India, each characterized by diverse climatic conditions having an operational life of two to ten years. A series of tests conforming to IEC 62852 incorporating C-AST is conducted on connectors encompassing both field-aged and control samples. Thereafter these samples and new field-aged samples underwent SEM for further analysis. The objective of these investigations was to elucidate the mechanisms of aging and evaluate the reliability of connectors, identify failure modes, potential hazards, and changes in electrical and mechanical performance because of longstanding exposure to environmental and operational stresses. The on-site field survey and testing reveal lack of awareness of the workmanship and maintenance of connectors. Samples having less than six years of operational life exhibit low contact resistance and remain relatively stable after undergoing C-AST. However, samples with operational life of six years or more from extreme climatic regions exhibited a high contact resistance in a nonlinear pattern beyond the permissible limits with values of contact resistance drastically. In SEM analysis, corrosion and fretting was observed on connectors which had shown high contact resistance with marginal polymer (outer insulation casing) deterioration.

The data has three files ,

The first file consists of general testing which were performed on 27 connectors in a laboratory, including contact resistance, dielectric voltage, insulation resistance IP, and glow wire test. As the connectors had different lengths of 4 sq mm cables, the contact resistance of the whole sample was first measured and then the cable resistance was subtracted from the initial value to get the contact resistance of the connector.

The second file consists of thermal cycling tests where a separate set of 16 connector samples comprising of control and field-aged connectors is subjected to a thermal cycling test for 1000 hrs with 200 cycles as per laid out norms where the connector is subjected to repeated cycles of temperatures of -40 to 105 °C. After every 100 cycles, the contact resistance of connectors is measured and finally, the dielectric strength test and IP test are conducted followed by the contact resistance test. Finally, the glow wire test is conducted on the samples. The connector is then examined for signs of damage or degradation, such as corrosion or changes in material properties after this test.

The third file consists of Damp heat testing where a separate set of 14 control and field-aged connectors for 7 cycles for a total of 1416 hrs though the standard norms specify only 1000 hrs. However, more stress was put on to the connectors for establishing a pattern of failure. In each cycle, the connector is exposed to a continuous temperature of 85C and 85% humidity environment, and again after each cycle, the contact resistance test is repeated followed by tests as mentioned in thermal cycling after the termination of damp heat testing. After this test, the connector is examined for any signs of damage or degradation, such as corrosion or changes in material properties.