Datasets

Standard Dataset

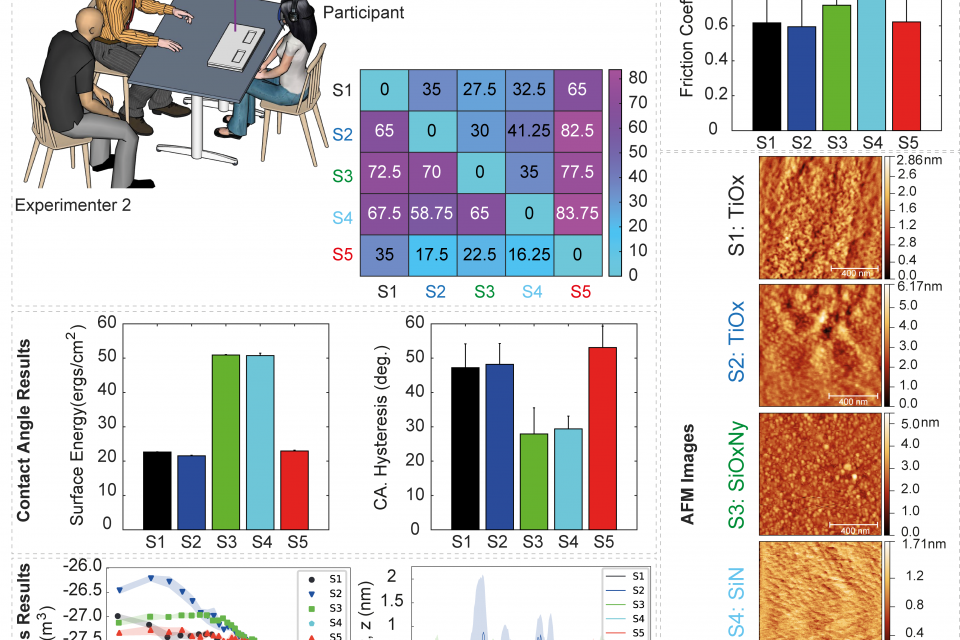

Tactile Perception of Coated Smooth Surfaces

- Citation Author(s):

- Submitted by:

- Easa AliAbbasi

- Last updated:

- Mon, 07/08/2024 - 15:58

- DOI:

- 10.21227/bw4t-g724

- Data Format:

- License:

63 Views

63 Views- Categories:

- Keywords:

Abstract

Although surface coating is commonly utilized in many industries for improving the aesthetics and functionality of the end product, our tactile perception of coated surfaces has not been investigated in depth yet. In fact, there are only a few studies investigating the effect of coating material on our tactile perception of extremely smooth surfaces having roughness amplitudes in the order of a few nanometers. Moreover, the current literature needs more studies linking the physical measurements performed on these surfaces to our tactile perception in order to further understand the adhesive contact mechanism leading to our percept. In this study, we first perform 2AFC experiments with 8 participants to quantify their tactile discrimination ability of 5 smooth glass surfaces coated with 3 different materials. We then measure the coefficient of friction between human finger and those 5 surfaces via a custom-made tribometer and their surface energies via Sessile drop test performed with 4 different liquids. The results of our psychophysical experiments and the physical measurements show that coating material has a strong influence on our tactile perception and human finger is capable of detecting differences in surface chemistry due to, possibly, molecular interactions.

- Atomic Force Microscope (AFM) Data: .nid files are raw AFM data and can be accessed using Gwyddion software. The raw data is filtered, and the results are saved inside the folder named "afm-analysis". Use "main.py" file to generate all results related to the AFM data, including surface roughness parameters and power spectrum densities.

- Contact Angle Data: Both static and dynamic contact angle data are available. Run "CAM_Static.m" file for static contact angle results, and then run either "SurfaceEnergy.m" or "SurfaceEnergy.py" to calculate surface free energies. Run "CAM_Dynamic.m" file for dynamic contact angle and contact angle hysteresis results.

- Frictional Forces Data: Run "FrictionAnalysis.m" file and it will generate and save all results of tangential forces, normal forces, and friction coefficients.

- Perception Data: Run "evaluation.m" file to generate the confusion matrix for each participant. It also generates average results.

Comments

Thank you