Bending and pressure sensor dataset

- Citation Author(s):

-

Xin Dong (Chongqing University of Technology)

- Submitted by:

- Xin Dong

- Last updated:

- DOI:

- 10.21227/aewf-ym25

- Data Format:

289 views

289 views

- Categories:

- Keywords:

Abstract

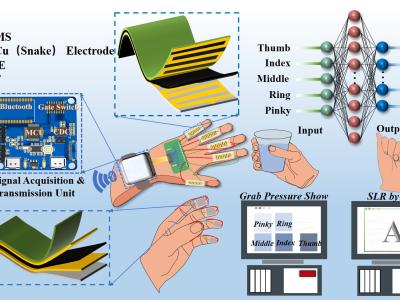

Flexible tactile sensors have attracted significant interest in robotics, medical monitoring, and wearable devices. This paper presents a capacitive flexible tactile sensor that employs a nickel carbonyl powder (NCP)-silicone rubber (SR) composite for pressure and bending sensing, fabricated using magnetic field curing. The performance of the sensor is evaluated independently for pressure and bending sensing, including sensitivity, response time, repeatability, and cyclic stability. The pressure sensor exhibits a notable capacitance changing of 171.9% within the range of 0-41 kPa, demonstrating fast (80 ms) responses and (120 ms) recovery times, and indicates excellent repeatability under different peak pressure ranging from 2-15KPa. It also shows excellent stability across 5000 repeated compression tests. Meanwhile, the bending sensor reveal a significant capacitance changing of 108% at ranging from 0-180°, with rapid (80 ms) responses and (48 ms) recovery times, and indicates stable repeatability under different peak angle ranging from 60-150°. Its reliable cyclic stability is confirmed through 1000 bending cyclic tests. Furthermore, the microscopic properties of magnetorheological elastomers (MRE) are further elucidated. Notably, the sensor is integrated into a breathable, lightweight glove, facilitating feedback on grasping pressure and enabling sign language recognition (SLR). When paired with machine learning (ML), it achieves an impressive accuracy of 97.73% in SLR. Overall, this research advances the development of flexible tactile sensors and highlights their considerable potential in human-computer interaction, medical health, wearable devices.

Instructions:

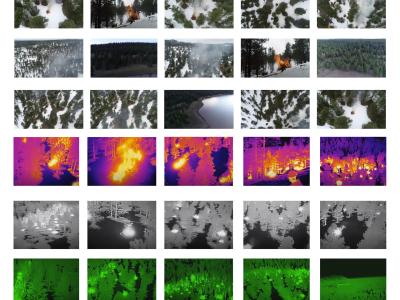

The image and data are from the submitted journal paper, the image is divided into data diagram and schematic diagram, and the data is the data of the sensor in the actual measurement

All experimental data are real measured data