Steel Industry Energy Consumption

- Citation Author(s):

- Submitted by:

- SATHISHKUMAR EASWARAMOORTHY

- Last updated:

- DOI:

- 10.21227/112a-dk82

- Links:

2039 views

2039 views

- Categories:

- Keywords:

Abstract

The fast development of urban advancement in the past decade requires reasonable and realistic solutions for transport, building infrastructure, natural conditions, and personal satisfaction in smart cities. This paper presents and explores predictive energy consumption models based on data-mining techniques for a smart small-scale steel industry in South Korea. Energy consumption data is collected using IoT based systems and used for prediction. Data used include the lagging and leading current reactive power, the lagging and leading current power factor, carbon dioxide emissions, and load types. Five statistical algorithms are used for energy consumption prediction:(a) General linear regression, (b) Classification and regression trees, (c) Support vector machine with a radial basis kernel, (d) K nearest neighbours, (e) CUBIST. Root mean squared error, Mean absolute error and Coefficient of variation are used to measure the prediction efficiency of the models. The results show that CUBIST model provides best results with lower error values and this model can be used for the development of energy efficient structural design which helps to optimize the energy consumption and policy making in smart cities.

Instructions:

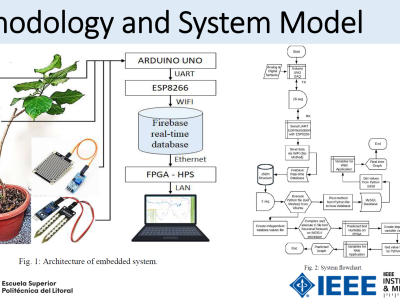

The information gathered is from the DAEWOO Steel Co. Ltd in Gwangyang, South Korea. It produces several types of coils, steel plates, and iron plates. The information on electricity consumption is held in a cloud-based system.

This dataset focuses on the energy data (in Kwh) recorded for the industry every 15 min. The reporting interval of 15 min was selected to track rapid energy consumption variations. The data time period is 365 days (12 months)