Industrial Internet of Things embedded devices fault detection and classification. A case study

- Citation Author(s):

-

Alberto Garcés-Jiménez

(Department of Computer Science, Universidad de Alcalá, 28805 Alcalá de Henares, Spain)

André Rodrigues (Polytechnic of Coimbra, Coimbra Business School Research Centre, ISCAC, Coimbra, 3040-316, Portugal)José M. Gómez-Pulido(Department of Computer Science, Universidad de Alcalá, Alcalá de Henares, Spain)

Duarte Raposo (Instituto de Telecomunicações, Aveiro, 3810-193, Portugal) - Submitted by:

- Juan A. Gomez-Pulido

- Last updated:

- DOI:

- 10.21227/x2xm-xh92

- Data Format:

1087 views

1087 views

- Categories:

- Keywords:

Abstract

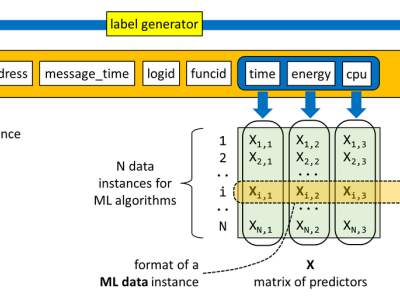

Industries transition to the Industry 4.0 paradigm requires solutions based on devices attached to machines that allow monitoring and control of industrial equipment. Monitoring is essential to ensure devices' proper operation against different aggressions. We propose a novel approach to detect and classify faults, that are typical in these devices, based on machine learning techniques that use as features the energy, the processing, and the time consumed by device main application functionality. The proposal was validated using a dataset collected from a testbed executing a typical equipment monitoring application. The proposal machine learning pipeline uses a decision tree-based model for fault detection (99.4% accuracy, 99.7% precision, 99.6% recall, 75.2% specificity, and 99.7% F1) followed by a Semi-Supervised Graph-Based model (99.3% accuracy, 96.4% precision, 96.1% recall, 99.6% specificity, and 96.2% F1) for further fault classification. Those results demonstrate that machine learning techniques, based on easily obtainable metrics, help coping with common device faults.

Instructions:

Instructions for dataset use.

Thanks